Model 933-S

デフラグレーション/デトネーション短時間燃焼式フレームアレスター

性能

- インラインデフラグレーション/デトネーションフレームアレスター

- 安定 / 不安定デトネーション

- 時間燃焼

- 低圧力損失

- 高い作動圧力と温度に対応する様々なオプションが利用可能

- ATEX 指令 2014/34/EU、EN ISO 16852:2016に準拠

- 公称で利用可能。直径: DN50 (2インチ)、DN600 (24インチ)

- ご要望により追加サイズも可能

お問い合わせはこちらから

Protection

- Gas/air or vapour / air-mixtures for explosion groups up to and including IIC (NEC Group B), MESG < 0.5mm

- Temperature Sensor – resistance thermometer with protection type

- Inherently safe (EEx i)

- Pressure Resistant Enclosure (EEx d)

Connection Type

- ISO 7005-1

- ASME B16.5

- ANSI B16.5

- Other types available upon request

Compliance with Guidelines

- ATEX 2014/34/EU

- EN ISO 16852:2016

Materials of Construction

| Carbon Steel | Stainless Steel | Hastelloy | Ductile Iron | Other Materials on request | |

|---|---|---|---|---|---|

| Metal Foil Element | ✓ | ✓ | ✓ | ||

| Housing of Metal Foil Element | ✓ | ✓ | ✓ | ||

| Body / Cover | ✓ | ✓ | ✓ | ✓ |

Painting Options Available

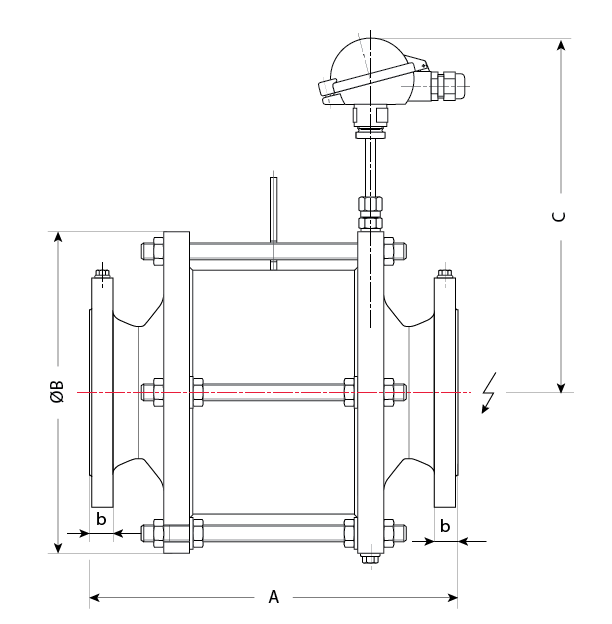

Dimensions

| DN | A* | ØB | C | b | Weight | |||||||||||||||||||||||

| N=2 | N=3 | N=4 | N=5 | N=6 | N=7 | N=8 | N=2 | N=3 | N=4 | N=5 | N=6 | N=7 | N=8 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | kg | kg | kg | kg | kg | kg | kg |

| 1.5 | 40 | 215 | 227 | 239 | 252 | 264 | 276 | 288 | 206 | 290 | 18 | 19 | 21 | 22 | 24 | 26 | 28 | 30 | ||||||||||

| 2 | 50 | 235 | 248 | 260 | 272 | 284 | 296 | 309 | 226 | 300 | 19 | 22 | 22 | 25 | 27 | 29 | 31 | 33 | ||||||||||

| 2.5 | 65 | 240 | 252 | 265 | 277 | 289 | 301 | 313 | 272 | 320 | 20 | 34 | 34 | 38 | 40 | 43 | 45 | 47 | ||||||||||

| 3 | 80 | 265 | 277 | 289 | 302 | 314 | 326 | 338 | 308 | 340 | 22 | 42 | 45 | 47 | 50 | 52 | 55 | 57 | ||||||||||

| 4 | 100 | 280 | 292 | 304 | 317 | 329 | 341 | 353 | 368 | 370 | 24 | 56 | 61 | 66 | 71 | 76 | 80 | 84 | ||||||||||

| 5 | 125 | 288 | 300 | 312 | 324 | 336 | 349 | 361 | 308 | 340 | 20.5 | 43 | 44 | 46 | 49 | 51 | 53 | 55 | ||||||||||

| 6 | 150 | |||||||||||||||||||||||||||

| 8 | 200 | |||||||||||||||||||||||||||

| 10 | 250 | |||||||||||||||||||||||||||

| 12 | 300 | |||||||||||||||||||||||||||

| 14 | 350 | |||||||||||||||||||||||||||

| 16 | 400 | |||||||||||||||||||||||||||

* N: number of metal foil elements

Product Literature

Installations

Protection

- Gas/air or vapour / air-mixtures for explosion groups up to and including IIC (NEC Group B), MESG < 0.5mm

- Temperature Sensor – resistance thermometer with protection type

- Inherently safe (EEx i)

- Pressure Resistant Enclosure (EEx d)

Connection Type

- ISO 7005-1

- ASME B16.5

- ANSI B16.5

- Other types available upon request

Compliance with Guidelines

- ATEX 2014/34/EU

- EN ISO 16852:2016

Materials of Construction

| Carbon Steel | Stainless Steel | Hastelloy | Ductile Iron | Other Materials on request | |

|---|---|---|---|---|---|

| Metal Foil Element | ✓ | ✓ | ✓ | ||

| Housing of Metal Foil Element | ✓ | ✓ | ✓ | ||

| Body / Cover | ✓ | ✓ | ✓ | ✓ |

Painting Options Available

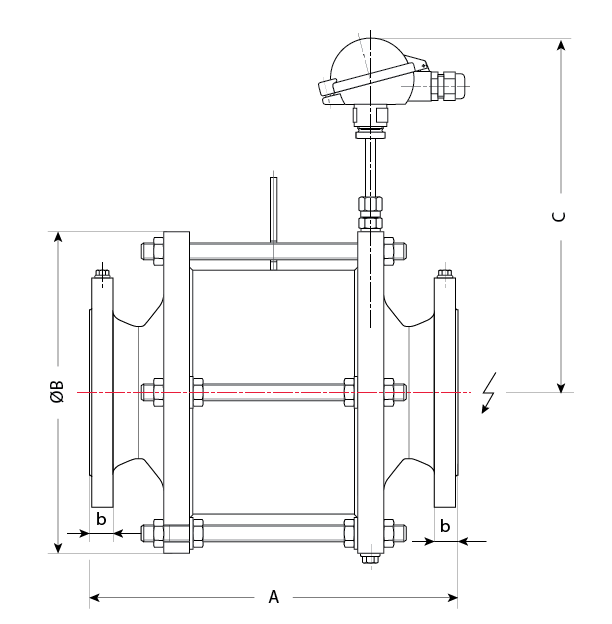

Dimensions

| DN | A* | ØB | C | b | Weight | |||||||||||||||||||||||

| N=2 | N=3 | N=4 | N=5 | N=6 | N=7 | N=8 | N=2 | N=3 | N=4 | N=5 | N=6 | N=7 | N=8 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | kg | kg | kg | kg | kg | kg | kg |

| 1.5 | 40 | 215 | 227 | 239 | 252 | 264 | 276 | 288 | 206 | 290 | 18 | 19 | 21 | 22 | 24 | 26 | 28 | 30 | ||||||||||

| 2 | 50 | 235 | 248 | 260 | 272 | 284 | 296 | 309 | 226 | 300 | 19 | 22 | 22 | 25 | 27 | 29 | 31 | 33 | ||||||||||

| 2.5 | 65 | 240 | 252 | 265 | 277 | 289 | 301 | 313 | 272 | 320 | 20 | 34 | 34 | 38 | 40 | 43 | 45 | 47 | ||||||||||

| 3 | 80 | 265 | 277 | 289 | 302 | 314 | 326 | 338 | 308 | 340 | 22 | 42 | 45 | 47 | 50 | 52 | 55 | 57 | ||||||||||

| 4 | 100 | 280 | 292 | 304 | 317 | 329 | 341 | 353 | 368 | 370 | 24 | 56 | 61 | 66 | 71 | 76 | 80 | 84 | ||||||||||

| 5 | 125 | 288 | 300 | 312 | 324 | 336 | 349 | 361 | 308 | 340 | 20.5 | 43 | 44 | 46 | 49 | 51 | 53 | 55 | ||||||||||

| 6 | 150 | |||||||||||||||||||||||||||

| 8 | 200 | |||||||||||||||||||||||||||

| 10 | 250 | |||||||||||||||||||||||||||

| 12 | 300 | |||||||||||||||||||||||||||

| 14 | 350 | |||||||||||||||||||||||||||

| 16 | 400 | |||||||||||||||||||||||||||

* N: number of metal foil elements