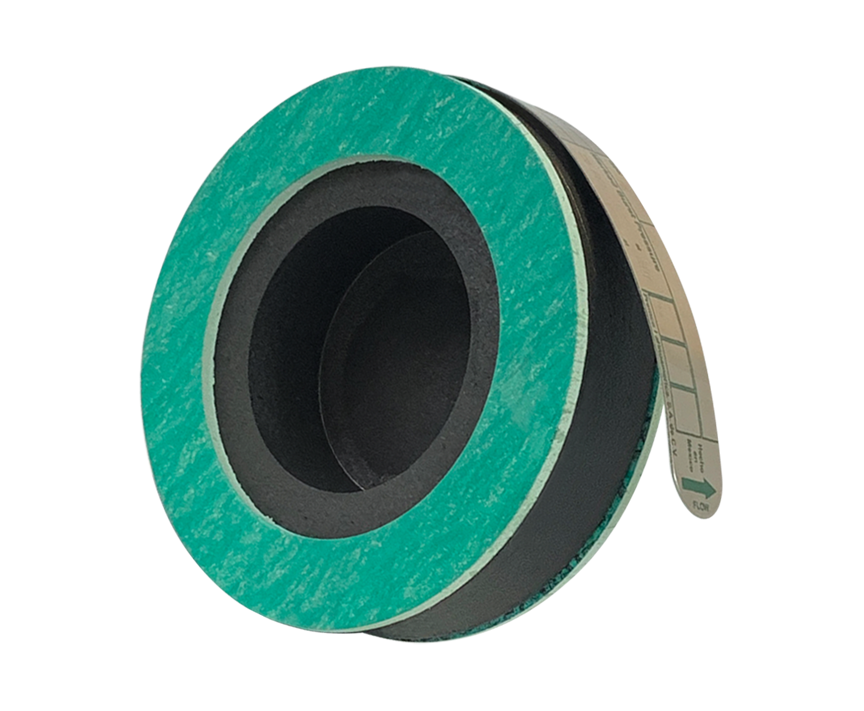

MB™

低圧グラファイトディスク

性能

お問い合わせはこちらから

Sizes & Pressures

MB™ , MBV™, AMB™, AMBV™ Disk Specifications Minimum/Maximum Pressure with Rating at 72° (22°C)

| Disk Size | Burst Pressure | Disk Thickness | ANSI Flange Rating | DIN | |||||

| psig | barg | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| in | mm | min | max | min | max | in | mm | ||

| 0.5 | 15 | 25 | 150 | 1.7 | 10.3 | 0.6 | 16 | 150 | 10/16 |

| 0.75 | 20 | 25 | 150 | 1.7 | 10.3 | 0.6 | 16 | 150 | 10/16 |

| 1 | 25 | 10 | 150 | 0.7 | 10.3 | 0.9 | 22 | 150 | 10/16 |

| 1.5 | 40 | 7 | 150 | 0.5 | 10.3 | 0.9 | 22 | 150 | 10/16 |

| 2 | 50 | 2 | 150 | 0.1 | 10.3 | 0.9 | 22 | 150 | 10/16 |

| 3 | 80 | 1 | 150 | 0.1 | 10.3 | 0.9 | 22 | 150 | 10/16 |

| 4 | 100 | 1 | 150 | 0.1 | 10.3 | 0.9 | 22 | 150 | 10/16 |

| 6 | 150 | 1 | 150 | 0.1 | 10.3 | 0.9 | 22 | 150 | 10/16 |

| 8 | 200 | 0.5 | 150 | 0.04 | 10.3 | 1.1 | 29 | 150 | 10/16 |

| 10 | 250 | 0.25 | 125 | 0.02 | 8.6 | 1.5 | 38 | 150 | 10/16 |

| 12 | 300 | 0.25 | 125 | 0.02 | 8.6 | 2 | 51 | 150 | 10/16 |

| 14 | 350 | 0.25 | 100 | 0.02 | 6.9 | 2.3 | 57 | 150 | 10/16 |

| 16 | 400 | 0.25 | 100 | 0.02 | 6.9 | 2.5 | 64 | 150 | 10/16 |

| 18 | 450 | 0.25 | 100 | 0.02 | 6.9 | 2.8 | 70 | 150 | 10/16 |

| 20 | 500 | 0.25 | 50 | 0.02 | 3.4 | 3 | 76 | 150 | 10/16 |

| 24 | 600 | 0.25 | 50 | 0.02 | 3.4 | 3 | 76 | 150 | 10/16 |

Burst Tolerance

| Marked Burst Pressure | Burst Tolerance |

|---|---|

| < 1 psig (0.07 barg) | -0/+0.75 psig (0/0.05 barg) |

| 1 – 15 psig (0.07 barg < 1.03 barg) | ± 0.75 psig (0.05 barg) |

| > 15 psig (1.03 barg) | ± 5% |

Example: If a Saf-T-Graf MB type disk is ordered with a 29 psig (2 bar) burst pressure, it will burst between 27.5 psig (1.9 bar) and 30.5 psig (2.1 bar). For reduced tolerances contact BS&B.

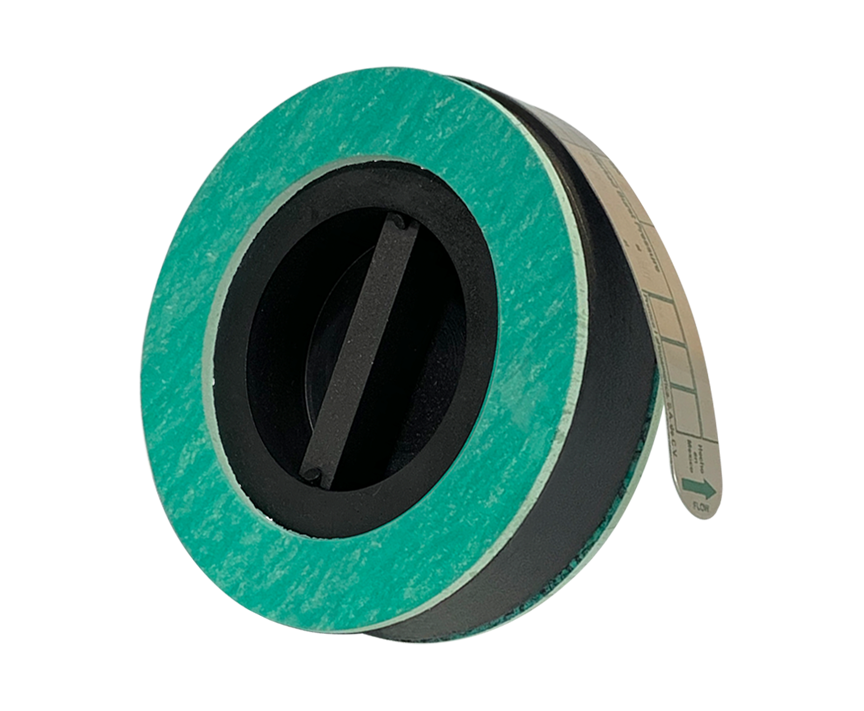

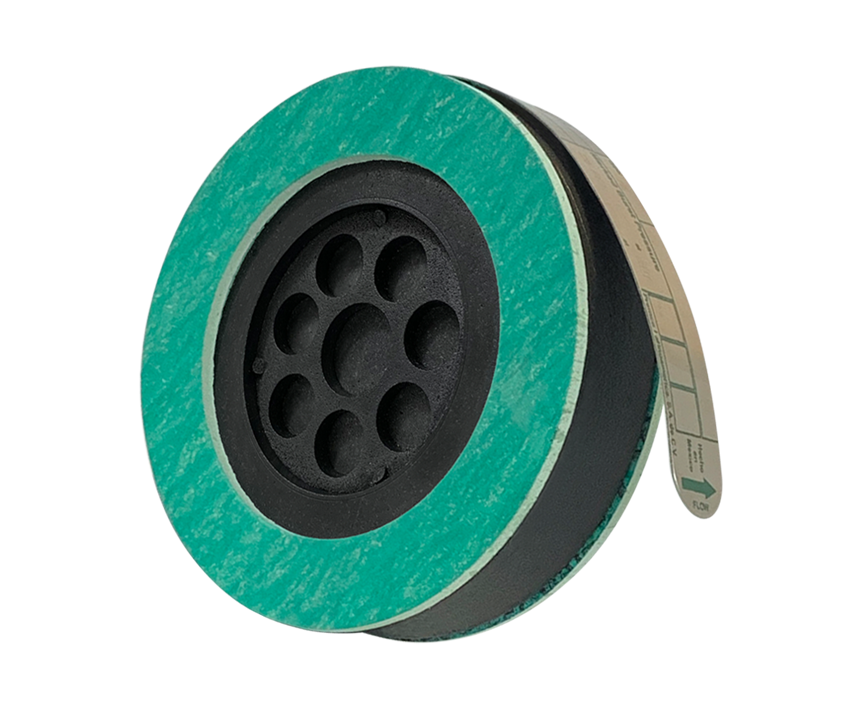

Vacuum Support

For Vacuum support order as MBV or AMBV (armored support). Vacuum support is necessary under the following application conditions:- Burst pressure is below 22 psig (1.52 barg) and full vacuum may be present (-14.5 psi / -1 barg)

- Vacuum exceeds 30% of burst pressure. For example, a 10 psig (0.7 barg) burst pressure disk will experience a -3 psig (-0.2 barg) vacuum

- Cycling between vacuum conditions and positive pressure may occur and burst pressure is below 22 psig (1.52 barg)

- Vacuum supports are needed for disks rated below 22 psig (1.52 bar) and where a vacuum condition exists. Model MBV or AMBV vacuum supports are not required on 0.5 and 0.75 inch (15 and 20 mm) monobloc disks

- Temperature ranges -100º to 400ºF (-73º to 205ºC). For further clarification on when to use a vacuum support, consult factory

For venting capacities necessary for vacuum support click here.

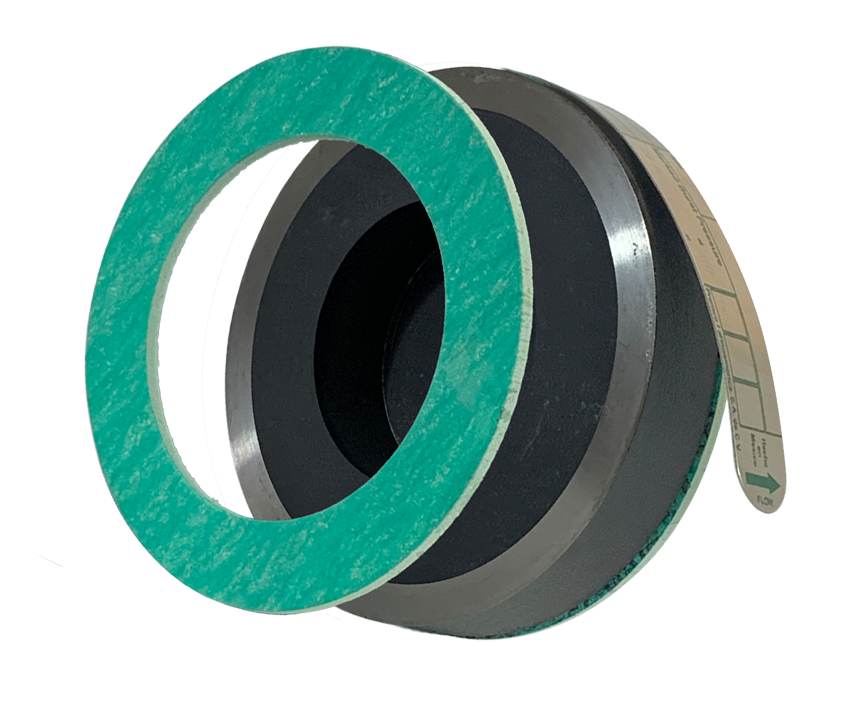

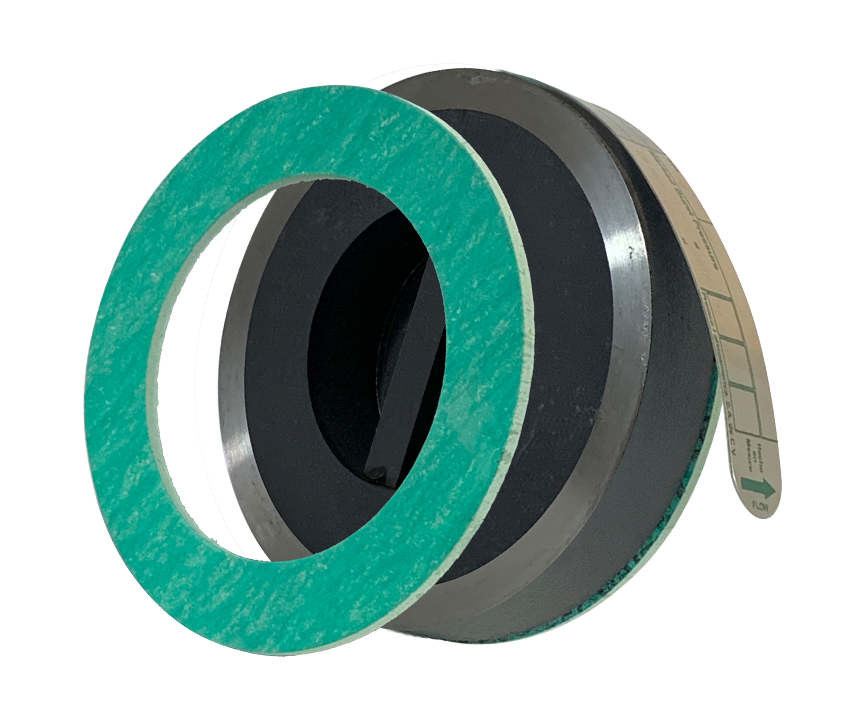

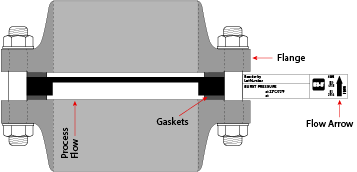

Armored Option

Armor is recommended for all graphite disks for added safety and elimination of breakage during installation. Armor consists of a steel ring encircling the outside diameter of the graphite rupture disk.

Armor is standard on disks with burst pressures in excess of 150 psig or to fit ANSI Class 300 / 600 flanges. Carbon steel armor is standard with 300 series stainless steel as an option. Armor is recommended for applications where lateral blow out / loss of containment represents a safety concern.

Armor for disks sizes shown when rated pressures equal to or exceed values in the below chart.

| Size | Burst Pressure | ||

| in | mm | psig | barg |

|---|---|---|---|

| 0.5-3 | 15-80 | 150 | 10.3 |

| 4 | 100 | 100 | 6.9 |

| 6-10 | 75 | 75 | 5.2 |

| 12-24 | 50 | 50 | 3.5 |

Sizes & Pressures

MB™ , MBV™, AMB™, AMBV™ Disk Specifications Minimum/Maximum Pressure with Rating at 72° (22°C)

| Disk Size | Burst Pressure | Disk Thickness | ANSI Flange Rating | DIN | |||||

| psig | barg | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| in | mm | min | max | min | max | in | mm | ||

| 0.5 | 15 | 25 | 150 | 1.7 | 10.3 | 0.6 | 16 | 150 | 10/16 |

| 0.75 | 20 | 25 | 150 | 1.7 | 10.3 | 0.6 | 16 | 150 | 10/16 |

| 1 | 25 | 10 | 150 | 0.7 | 10.3 | 0.9 | 22 | 150 | 10/16 |

| 1.5 | 40 | 7 | 150 | 0.5 | 10.3 | 0.9 | 22 | 150 | 10/16 |

| 2 | 50 | 2 | 150 | 0.1 | 10.3 | 0.9 | 22 | 150 | 10/16 |

| 3 | 80 | 1 | 150 | 0.1 | 10.3 | 0.9 | 22 | 150 | 10/16 |

| 4 | 100 | 1 | 150 | 0.1 | 10.3 | 0.9 | 22 | 150 | 10/16 |

| 6 | 150 | 1 | 150 | 0.1 | 10.3 | 0.9 | 22 | 150 | 10/16 |

| 8 | 200 | 0.5 | 150 | 0.04 | 10.3 | 1.1 | 29 | 150 | 10/16 |

| 10 | 250 | 0.25 | 125 | 0.02 | 8.6 | 1.5 | 38 | 150 | 10/16 |

| 12 | 300 | 0.25 | 125 | 0.02 | 8.6 | 2 | 51 | 150 | 10/16 |

| 14 | 350 | 0.25 | 100 | 0.02 | 6.9 | 2.3 | 57 | 150 | 10/16 |

| 16 | 400 | 0.25 | 100 | 0.02 | 6.9 | 2.5 | 64 | 150 | 10/16 |

| 18 | 450 | 0.25 | 100 | 0.02 | 6.9 | 2.8 | 70 | 150 | 10/16 |

| 20 | 500 | 0.25 | 50 | 0.02 | 3.4 | 3 | 76 | 150 | 10/16 |

| 24 | 600 | 0.25 | 50 | 0.02 | 3.4 | 3 | 76 | 150 | 10/16 |

Burst Tolerance

| Marked Burst Pressure | Burst Tolerance |

|---|---|

| < 1 psig (0.07 barg) | -0/+0.75 psig (0/0.05 barg) |

| 1 – 15 psig (0.07 barg < 1.03 barg) | ± 0.75 psig (0.05 barg) |

| > 15 psig (1.03 barg) | ± 5% |

Example: If a Saf-T-Graf MB type disk is ordered with a 29 psig (2 bar) burst pressure, it will burst between 27.5 psig (1.9 bar) and 30.5 psig (2.1 bar). For reduced tolerances contact BS&B.

Vacuum Support

For Vacuum support order as MBV or AMBV (armored support). Vacuum support is necessary under the following application conditions:- Burst pressure is below 22 psig (1.52 barg) and full vacuum may be present (-14.5 psi / -1 barg)

- Vacuum exceeds 30% of burst pressure. For example, a 10 psig (0.7 barg) burst pressure disk will experience a -3 psig (-0.2 barg) vacuum

- Cycling between vacuum conditions and positive pressure may occur and burst pressure is below 22 psig (1.52 barg)

- Vacuum supports are needed for disks rated below 22 psig (1.52 bar) and where a vacuum condition exists. Model MBV or AMBV vacuum supports are not required on 0.5 and 0.75 inch (15 and 20 mm) monobloc disks

- Temperature ranges -100º to 400ºF (-73º to 205ºC). For further clarification on when to use a vacuum support, consult factory

For venting capacities necessary for vacuum support click here.

Armored Option

Armor is recommended for all graphite disks for added safety and elimination of breakage during installation. Armor consists of a steel ring encircling the outside diameter of the graphite rupture disk.

Armor is standard on disks with burst pressures in excess of 150 psig or to fit ANSI Class 300 / 600 flanges. Carbon steel armor is standard with 300 series stainless steel as an option. Armor is recommended for applications where lateral blow out / loss of containment represents a safety concern.

Armor for disks sizes shown when rated pressures equal to or exceed values in the below chart.

| Size | Burst Pressure | ||

| in | mm | psig | barg |

|---|---|---|---|

| 0.5-3 | 15-80 | 150 | 10.3 |

| 4 | 100 | 100 | 6.9 |

| 6-10 | 75 | 75 | 5.2 |

| 12-24 | 50 | 50 | 3.5 |