IMB™

低/高圧グラファイトディスク

性能

お問い合わせはこちらから

Sizes & Pressures

IMB™, AIMB™, IMBL™ and AIMBL™ Disk Specifications Minimum/Maximum Pressure with Rating at 72° (22°C)

| Disk Size | Burst Pressure | Disk Thickness | ANSI Flange Rating | DIN | |||||

| psig | barg | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| in | mm | min | max | min | max | in | mm | ||

| 0.5 | 15 | 25 | 250 | 1.7 | 17 | 0.6 | 16 | 150 | 10/16 |

| 0.5 | 15 | 25 | 1000 | 1.7 | 69 | 0.6 | 16 | 300/600 | 25/40 |

| 0.75 | 20 | 25 | 250 | 1.7 | 17 | 0.6 | 16 | 150 | 10/16 |

| 0.75 | 20 | 25 | 1000 | 1.7 | 69 | 0.6 | 16 | 300/600 | 25/40 |

| 1 | 25 | 10 | 250 | 0.7 | 17 | 0.9 | 22 | 150 | 10/16 |

| 1 | 25 | 10 | 1000 | 0.7 | 69 | 0.9 | 25 | 300/600 | 25/40 |

| 1.5 | 40 | 7 | 250 | 0.5 | 17 | 0.9 | 22 | 150 | 10/16 |

| 1.5 | 40 | 7 | 1000 | 0.5 | 69 | 1.0 | 25 | 300/600 | 25/40 |

| 2 | 50 | 2 | 250 | 0.1 | 10.3 | 0.9 | 22 | 150 | 10/16 |

| 2 | 50 | 3 | 500 | 0.2 | 34 | 1.0 | 25 | 300/600 | 25/40 |

| 3 | 80 | 1 | 250 | 0.1 | 17 | 0.9 | 22 | 150 | 10/16 |

| 3 | 80 | 2 | 500 | 0.1 | 34 | 1.2 | 32 | 300 | 25/40 |

| 4 | 100 | 1 | 250 | 0.1 | 17 | 0.9 | 22 | 150 | 10/16 |

| 4 | 100 | 1.5 | 500 | 0.1 | 34 | 1.3 | 32 | 300 | 25/40 |

| 6 | 150 | 1 | 170 | 0.1 | 12 | 0.9 | 22 | 150 | 10/16 |

| 6 | 150 | 1 | 450 | 0.1 | 31 | 1.8 | 44 | 300 | 25/40 |

| 8 | 200 | 0.5 | 170 | 0.04 | 12 | 1.1 | 29 | 150 | 10/16 |

| 8 | 200 | 0.5 | 450 | 0.04 | 31 | 2.3 | 57 | 300 | 25/40 |

| 10 | 250 | 0.3 | 150 | 0.02 | 10 | 1.5 | 38 | 150 | 10/16 |

| 12 | 300 | 0.3 | 150 | 0.02 | 10 | 2.0 | 51 | 150 | 10/16 |

| 14 | 350 | 0.3 | 150 | 0.02 | 10 | 2.3 | 57 | 150 | 10/16 |

| 16 | 400 | 0.3 | 150 | 0.02 | 10 | 2.5 | 64 | 150 | 10/16 |

| 18 | 450 | 0.3 | 150 | 0.02 | 10 | 2.8 | 70 | 150 | 10/16 |

| 20 | 500 | 0.3 | 150 | 0.02 | 10 | 3.0 | 76 | 150 | 10/16 |

| 24 | 600 | 0.3 | 150 | 0.02 | 3.4 | 3.0 | 76 | 150 | 10/16 |

Burst Tolerance

| Marked Burst Pressure | Burst Tolerance |

|---|---|

| < 1 psig (0.07 barg) | -0/+0.75 psig (0/0.05 barg) |

| 1 – 15 psig (0.07 barg < 1.03 barg) | ± 0.75 psig (0.05 barg) |

| > 15 psig (1.03 barg) | ± 5% |

Example: If a Saf-T-Graf IMB type disk is ordered with a 29 psig (2 bar) burst pressure, it will burst between 27.5 psig (1.9 bar) and 30.5 psig (2.1 bar). For reduced tolerances contact BS&B.

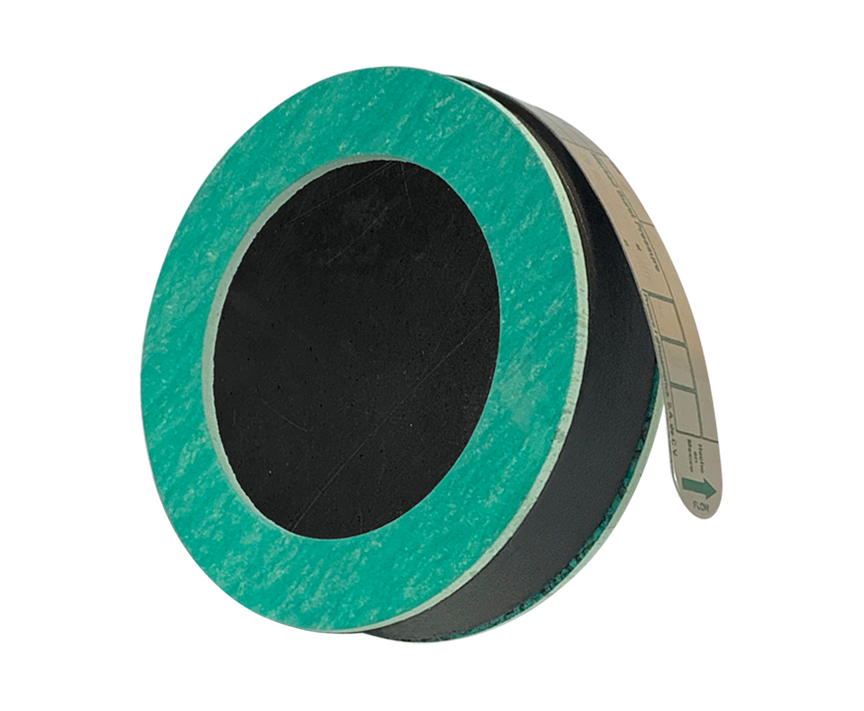

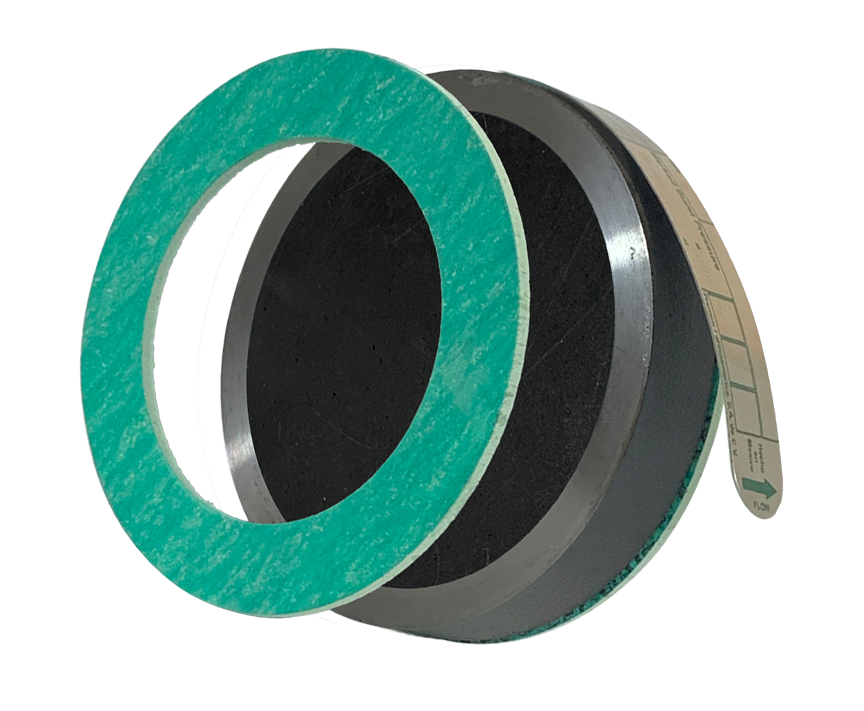

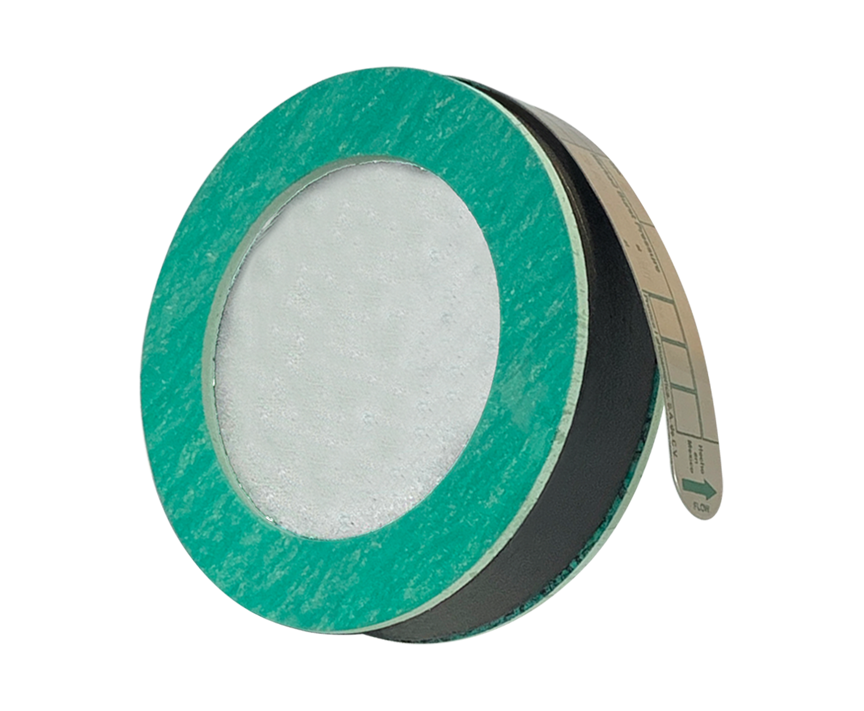

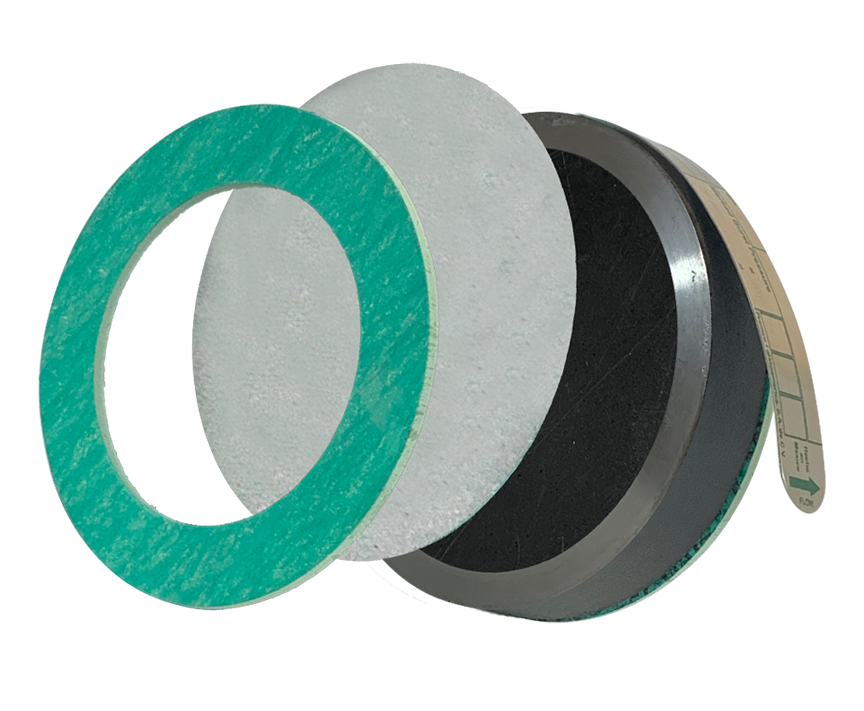

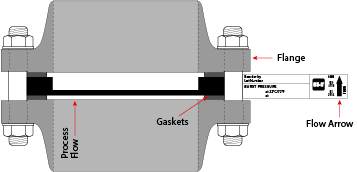

Armored Option

Armor is recommended for all graphite disks for added safety and elimination of breakage during installation. Armor consists of a steel ring encircling the outside diameter of the graphite rupture disk.

Armor is standard on disks with burst pressures in excess of 150 psig or to fit ANSI Class 300 / 600 flanges. Carbon steel armor is standard with 300 series stainless steel as an option. Armor is recommended for applications where lateral blow out / loss of containment represents a safety concern.

Armor for disks sizes shown when rated pressures equal to or exceed values in the below chart.

| Size | Burst Pressure | ||

| in | mm | psig | barg |

|---|---|---|---|

| 0.5-3 | 15-80 | 150 | 10.3 |

| 4 | 100 | 100 | 6.9 |

| 6-10 | 75 | 75 | 5.2 |

| 12-24 | 50 | 50 | 3.5 |

Sizes & Pressures

IMB™, AIMB™, IMBL™ and AIMBL™ Disk Specifications Minimum/Maximum Pressure with Rating at 72° (22°C)

| Disk Size | Burst Pressure | Disk Thickness | ANSI Flange Rating | DIN | |||||

| psig | barg | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| in | mm | min | max | min | max | in | mm | ||

| 0.5 | 15 | 25 | 250 | 1.7 | 17 | 0.6 | 16 | 150 | 10/16 |

| 0.5 | 15 | 25 | 1000 | 1.7 | 69 | 0.6 | 16 | 300/600 | 25/40 |

| 0.75 | 20 | 25 | 250 | 1.7 | 17 | 0.6 | 16 | 150 | 10/16 |

| 0.75 | 20 | 25 | 1000 | 1.7 | 69 | 0.6 | 16 | 300/600 | 25/40 |

| 1 | 25 | 10 | 250 | 0.7 | 17 | 0.9 | 22 | 150 | 10/16 |

| 1 | 25 | 10 | 1000 | 0.7 | 69 | 0.9 | 25 | 300/600 | 25/40 |

| 1.5 | 40 | 7 | 250 | 0.5 | 17 | 0.9 | 22 | 150 | 10/16 |

| 1.5 | 40 | 7 | 1000 | 0.5 | 69 | 1.0 | 25 | 300/600 | 25/40 |

| 2 | 50 | 2 | 250 | 0.1 | 10.3 | 0.9 | 22 | 150 | 10/16 |

| 2 | 50 | 3 | 500 | 0.2 | 34 | 1.0 | 25 | 300/600 | 25/40 |

| 3 | 80 | 1 | 250 | 0.1 | 17 | 0.9 | 22 | 150 | 10/16 |

| 3 | 80 | 2 | 500 | 0.1 | 34 | 1.2 | 32 | 300 | 25/40 |

| 4 | 100 | 1 | 250 | 0.1 | 17 | 0.9 | 22 | 150 | 10/16 |

| 4 | 100 | 1.5 | 500 | 0.1 | 34 | 1.3 | 32 | 300 | 25/40 |

| 6 | 150 | 1 | 170 | 0.1 | 12 | 0.9 | 22 | 150 | 10/16 |

| 6 | 150 | 1 | 450 | 0.1 | 31 | 1.8 | 44 | 300 | 25/40 |

| 8 | 200 | 0.5 | 170 | 0.04 | 12 | 1.1 | 29 | 150 | 10/16 |

| 8 | 200 | 0.5 | 450 | 0.04 | 31 | 2.3 | 57 | 300 | 25/40 |

| 10 | 250 | 0.3 | 150 | 0.02 | 10 | 1.5 | 38 | 150 | 10/16 |

| 12 | 300 | 0.3 | 150 | 0.02 | 10 | 2.0 | 51 | 150 | 10/16 |

| 14 | 350 | 0.3 | 150 | 0.02 | 10 | 2.3 | 57 | 150 | 10/16 |

| 16 | 400 | 0.3 | 150 | 0.02 | 10 | 2.5 | 64 | 150 | 10/16 |

| 18 | 450 | 0.3 | 150 | 0.02 | 10 | 2.8 | 70 | 150 | 10/16 |

| 20 | 500 | 0.3 | 150 | 0.02 | 10 | 3.0 | 76 | 150 | 10/16 |

| 24 | 600 | 0.3 | 150 | 0.02 | 3.4 | 3.0 | 76 | 150 | 10/16 |

Burst Tolerance

| Marked Burst Pressure | Burst Tolerance |

|---|---|

| < 1 psig (0.07 barg) | -0/+0.75 psig (0/0.05 barg) |

| 1 – 15 psig (0.07 barg < 1.03 barg) | ± 0.75 psig (0.05 barg) |

| > 15 psig (1.03 barg) | ± 5% |

Example: If a Saf-T-Graf IMB type disk is ordered with a 29 psig (2 bar) burst pressure, it will burst between 27.5 psig (1.9 bar) and 30.5 psig (2.1 bar). For reduced tolerances contact BS&B.

Armored Option

Armor is recommended for all graphite disks for added safety and elimination of breakage during installation. Armor consists of a steel ring encircling the outside diameter of the graphite rupture disk.

Armor is standard on disks with burst pressures in excess of 150 psig or to fit ANSI Class 300 / 600 flanges. Carbon steel armor is standard with 300 series stainless steel as an option. Armor is recommended for applications where lateral blow out / loss of containment represents a safety concern.

Armor for disks sizes shown when rated pressures equal to or exceed values in the below chart.

| Size | Burst Pressure | ||

| in | mm | psig | barg |

|---|---|---|---|

| 0.5-3 | 15-80 | 150 | 10.3 |

| 4 | 100 | 100 | 6.9 |

| 6-10 | 75 | 75 | 5.2 |

| 12-24 | 50 | 50 | 3.5 |