XT™ – Nu-Saf™

中圧十字切溝付き破裂板

性能

- プロセス側表面スムース仕上げで生成物の堆積を防止

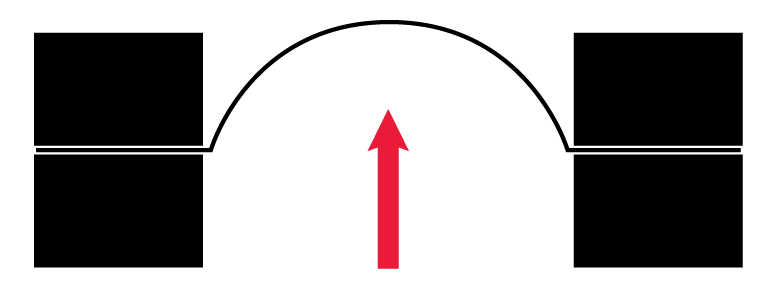

- 気相液相混合流体兼用

- 破裂圧力の80%まで運転可能(破裂誤差下限の85%まで)

- 破片飛散なし、安全弁一次側設置の推奨製品

- ダメージ安全率≤1(ダメージがある場合表示破裂圧力の1倍以下で破裂する)

- 周期的に圧力変動する運転状況に適している

- 真空耐性あり

- ASME “UD”スタンプ対応(製造範囲0%/-5%/-10%選定)

- 圧力機器指令”CE”マーク及びその他国際証書対応

- BS&B独占技術

お問い合わせはこちらから

Sizes & Pressures

XT™ Gas Service Disk Specifications Minimum/Maximum Pressure with Rating at 72° (22°C)

| Disk Size | Nickel Alloy 200 & Tantalum | Monel® Alloy 400 & Inconel® Alloy 600 | Hastelloy® Alloy C-276 | 316SS | Aluminum | ||||||||||||||||

| in | mm | psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | ||

| 1 | 25 | 165 | 1450 | 11 | 100 | 165 | 1450 | 11 | 100 | 240 | 1450 | 17 | 100 | 175 | 1450 | 12 | 100 | 80 | 1450 | 6 | 100 |

| 1.5 | 40 | 115 | 1450 | 8 | 100 | 115 | 1450 | 8 | 100 | 176 | 1450 | 12 | 100 | 125 | 1450 | 8.6 | 100 | 55 | 1450 | 4 | 100 |

| 2 | 50 | 105 | 1450 | 7 | 100 | 105 | 1450 | 7 | 100 | 160 | 1450 | 11 | 100 | 115 | 1450 | 8 | 100 | 45 | 1450 | 3 | 100 |

| 3 | 80 | 90 | 1300 | 6.2 | 90 | 90 | 1300 | 6.2 | 90 | 140 | 1300 | 10 | 90 | 100 | 1300 | 7 | 90 | 45 | 1300 | 3 | 100 |

| 4 | 100 | 90 | 1150 | 6.2 | 79 | 90 | 1150 | 6.2 | 79 | 140 | 1150 | 10 | 79 | 95 | 1150 | 7 | 79 | 40 | 1150 | 3 | 79 |

| 6 | 150 | 90 | 1040 | 6.2 | 71 | 90 | 1040 | 6.2 | 71 | 130 | 1040 | 9 | 72 | 90 | 1040 | 6.2 | 72 | 40 | 1040 | 3 | 72 |

| 8 | 200 | 85 | 960 | 5.9 | 66 | 85 | 960 | 5.9 | 66 | 130 | 960 | 9 | 66 | 90 | 960 | 6.2 | 66 | 40 | 960 | 3 | 66 |

| 10 | 250 | 85 | 840 | 5.9 | 58 | 85 | 840 | 5.9 | 58 | 125 | 840 | 8.6 | 58 | 90 | 840 | 6.2 | 58 | – | – | – | – |

| 12 | 300 | 85 | 720 | 5.9 | 49.6 | 85 | 720 | 5.9 | 49.6 | 125 | 720 | 8.6 | 49.6 | 90 | 720 | 6.2 | 49.6 | – | – | – | – |

XT™ Liquid Service Disk Specifications Minimum/Maximum Pressure with Rating at 72° (22°C)

| Disk Size | Nickel Alloy 200 & Tantalum | Monel® Alloy 400 & Inconel® Alloy 600 | Hastelloy® Alloy C-276 | 316SS | Aluminum | ||||||||||||||||

| in | mm | psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | ||

| 1 | 25 | 250 | 1450 | 17.2 | 100 | 250 | 1450 | 17.2 | 100 | 250 | 1450 | 17.2 | 100 | 250 | 1450 | 17.2 | 100 | 250 | 1450 | 17.2 | 100 |

| 1.5 | 40 | 150 | 1450 | 10.3 | 100 | 150 | 1450 | 10.3 | 100 | 200 | 1450 | 13.8 | 100 | 150 | 1450 | 10.3 | 100 | 150 | 1450 | 10.3 | 100 |

| 2 | 50 | 150 | 1450 | 10.3 | 100 | 150 | 1450 | 10.3 | 100 | 185 | 1450 | 12.7 | 100 | 150 | 1450 | 10.3 | 100 | 150 | 1450 | 10.3 | 100 |

| 3 | 80 | 150 | 1350 | 10.3 | 93.1 | 150 | 1350 | 10.3 | 93.1 | 150 | 1350 | 10.3 | 93.1 | 150 | 1350 | 10.3 | 93.1 | 150 | 1350 | 10.3 | 93.1 |

| 4 | 100 | 120 | 1150 | 8.3 | 79.3 | 130 | 1150 | 9 | 79.3 | 130 | 1150 | 9 | 79.3 | 130 | 1150 | 9 | 79.3 | 80 | 1150 | 5.5 | 79.3 |

| 6 | 150 | 90 | 1040 | 6.2 | 71.7 | 100 | 1040 | 6.9 | 71.7 | 150 | 1040 | 10.3 | 71.7 | 100 | 1040 | 6.9 | 71.7 | 70 | 1040 | 4.8 | 71.7 |

| 8 | 200 | 75 | 960 | 5.2 | 66.2 | 90 | 960 | 6.2 | 66.2 | 130 | 960 | 9 | 66.2 | 90 | 960 | 6.2 | 66.2 | 60 | 960 | 4.1 | 66.2 |

| 10 | 250 | 60 | 840 | 4.1 | 57.9 | 85 | 840 | 5.9 | 57.9 | 125 | 720 | 8.6 | 57.9 | 90 | 840 | 6.2 | 57.9 | – | – | – | – |

| 12 | 300 | 85 | 720 | 5.9 | 49.6 | 85 | 720 | 5.9 | 49.6 | 125 | 720 | 8.6 | 49.6 | 90 | 720 | 6.2 | 49.6 | – | – | – | – |

Burst Tolerance

| Marked Burst Pressure | Burst Tolerance |

|---|---|

| ≤ 40 psig (2.76 barg) | ± 2 psig (0.138 barg) |

| > 40 psig (2.76 barg) | ± 5% |

Accessories

BS&B supplies many of the accessories required to safely and conveniently install our overpressure relief devices and complementary products. Through our professional team and global network of sales engineers and procurement personnel, we are able to provide the highest quality accessory products to meet your installation requirements.

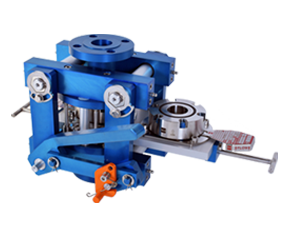

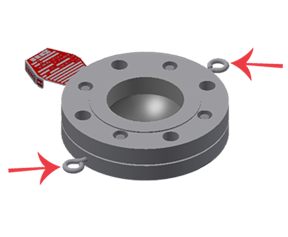

Saf-T-Change Quick Disk Replacement (QDR)

After activation, the replacement disk is quickly slid into place. Saving hours of lost production due to blown rupture disks.

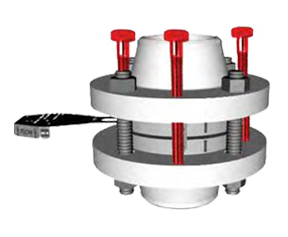

Tell-Tale Assemblies & Excess Flow Valves/Gauges

A gauge tap in the outlet flange of the safety head may be considered when the safety head is installed in a vertical position.

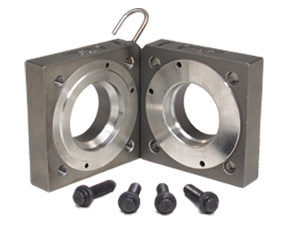

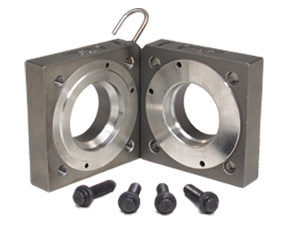

Spare Safety Heads & Cap Screws

Jackscrews

When activated, the jackscrews effectively separate the flanges, providing adequate clearance to remove or insert a safety head and external gaskets.

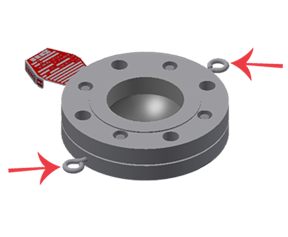

Lifting Lug Eye Bolts

Eye bolts are recommended when weight and/or accessibility is a factor in lifting safety heads.

Baffle Plate

When a safety head is free-vented to atmosphere, a baffle plate may be considered to disperse overpressure and absorb recoil.

Product Literature

Sizes & Pressures

XT™ Gas Service Disk Specifications Minimum/Maximum Pressure with Rating at 72° (22°C)

| Disk Size | Nickel Alloy 200 & Tantalum | Monel® Alloy 400 & Inconel® Alloy 600 | Hastelloy® Alloy C-276 | 316SS | Aluminum | ||||||||||||||||

| in | mm | psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | ||

| 1 | 25 | 165 | 1450 | 11 | 100 | 165 | 1450 | 11 | 100 | 240 | 1450 | 17 | 100 | 175 | 1450 | 12 | 100 | 80 | 1450 | 6 | 100 |

| 1.5 | 40 | 115 | 1450 | 8 | 100 | 115 | 1450 | 8 | 100 | 176 | 1450 | 12 | 100 | 125 | 1450 | 8.6 | 100 | 55 | 1450 | 4 | 100 |

| 2 | 50 | 105 | 1450 | 7 | 100 | 105 | 1450 | 7 | 100 | 160 | 1450 | 11 | 100 | 115 | 1450 | 8 | 100 | 45 | 1450 | 3 | 100 |

| 3 | 80 | 90 | 1300 | 6.2 | 90 | 90 | 1300 | 6.2 | 90 | 140 | 1300 | 10 | 90 | 100 | 1300 | 7 | 90 | 45 | 1300 | 3 | 100 |

| 4 | 100 | 90 | 1150 | 6.2 | 79 | 90 | 1150 | 6.2 | 79 | 140 | 1150 | 10 | 79 | 95 | 1150 | 7 | 79 | 40 | 1150 | 3 | 79 |

| 6 | 150 | 90 | 1040 | 6.2 | 71 | 90 | 1040 | 6.2 | 71 | 130 | 1040 | 9 | 72 | 90 | 1040 | 6.2 | 72 | 40 | 1040 | 3 | 72 |

| 8 | 200 | 85 | 960 | 5.9 | 66 | 85 | 960 | 5.9 | 66 | 130 | 960 | 9 | 66 | 90 | 960 | 6.2 | 66 | 40 | 960 | 3 | 66 |

| 10 | 250 | 85 | 840 | 5.9 | 58 | 85 | 840 | 5.9 | 58 | 125 | 840 | 8.6 | 58 | 90 | 840 | 6.2 | 58 | – | – | – | – |

| 12 | 300 | 85 | 720 | 5.9 | 49.6 | 85 | 720 | 5.9 | 49.6 | 125 | 720 | 8.6 | 49.6 | 90 | 720 | 6.2 | 49.6 | – | – | – | – |

XT™ Liquid Service Disk Specifications Minimum/Maximum Pressure with Rating at 72° (22°C)

| Disk Size | Nickel Alloy 200 & Tantalum | Monel® Alloy 400 & Inconel® Alloy 600 | Hastelloy® Alloy C-276 | 316SS | Aluminum | ||||||||||||||||

| in | mm | psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | ||

| 1 | 25 | 250 | 1450 | 17.2 | 100 | 250 | 1450 | 17.2 | 100 | 250 | 1450 | 17.2 | 100 | 250 | 1450 | 17.2 | 100 | 250 | 1450 | 17.2 | 100 |

| 1.5 | 40 | 150 | 1450 | 10.3 | 100 | 150 | 1450 | 10.3 | 100 | 200 | 1450 | 13.8 | 100 | 150 | 1450 | 10.3 | 100 | 150 | 1450 | 10.3 | 100 |

| 2 | 50 | 150 | 1450 | 10.3 | 100 | 150 | 1450 | 10.3 | 100 | 185 | 1450 | 12.7 | 100 | 150 | 1450 | 10.3 | 100 | 150 | 1450 | 10.3 | 100 |

| 3 | 80 | 150 | 1350 | 10.3 | 93.1 | 150 | 1350 | 10.3 | 93.1 | 150 | 1350 | 10.3 | 93.1 | 150 | 1350 | 10.3 | 93.1 | 150 | 1350 | 10.3 | 93.1 |

| 4 | 100 | 120 | 1150 | 8.3 | 79.3 | 130 | 1150 | 9 | 79.3 | 130 | 1150 | 9 | 79.3 | 130 | 1150 | 9 | 79.3 | 80 | 1150 | 5.5 | 79.3 |

| 6 | 150 | 90 | 1040 | 6.2 | 71.7 | 100 | 1040 | 6.9 | 71.7 | 150 | 1040 | 10.3 | 71.7 | 100 | 1040 | 6.9 | 71.7 | 70 | 1040 | 4.8 | 71.7 |

| 8 | 200 | 75 | 960 | 5.2 | 66.2 | 90 | 960 | 6.2 | 66.2 | 130 | 960 | 9 | 66.2 | 90 | 960 | 6.2 | 66.2 | 60 | 960 | 4.1 | 66.2 |

| 10 | 250 | 60 | 840 | 4.1 | 57.9 | 85 | 840 | 5.9 | 57.9 | 125 | 720 | 8.6 | 57.9 | 90 | 840 | 6.2 | 57.9 | – | – | – | – |

| 12 | 300 | 85 | 720 | 5.9 | 49.6 | 85 | 720 | 5.9 | 49.6 | 125 | 720 | 8.6 | 49.6 | 90 | 720 | 6.2 | 49.6 | – | – | – | – |

Burst Tolerance

| Marked Burst Pressure | Burst Tolerance |

|---|---|

| ≤ 40 psig (2.76 barg) | ± 2 psig (0.138 barg) |

| > 40 psig (2.76 barg) | ± 5% |

Accessories

BS&B supplies many of the accessories required to safely and conveniently install our overpressure relief devices and complementary products. Through our professional team and global network of sales engineers and procurement personnel, we are able to provide the highest quality accessory products to meet your installation requirements.

Saf-T-Change Quick Disk Replacement (QDR)

After activation, the replacement disk is quickly slid into place. Saving hours of lost production due to blown rupture disks.

Tell-Tale Assemblies & Excess Flow Valves/Gauges

A gauge tap in the outlet flange of the safety head may be considered when the safety head is installed in a vertical position.

Spare Safety Heads & Cap Screws

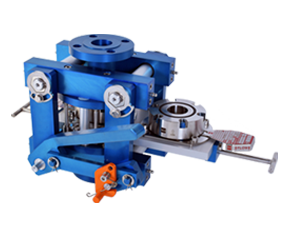

Jackscrews

When activated, the jackscrews effectively separate the flanges, providing adequate clearance to remove or insert a safety head and external gaskets.

Lifting Lug Eye Bolts

Eye bolts are recommended when weight and/or accessibility is a factor in lifting safety heads.

Baffle Plate

When a safety head is free-vented to atmosphere, a baffle plate may be considered to disperse overpressure and absorb recoil.