RE™

ホルダ用グラファイトディスク

性能

お問い合わせはこちらから

Sizes & Pressures

RE™, REL™, REV™ Disk Specifications Minimum/Maximum Pressure with Rating at 72° (22°C)

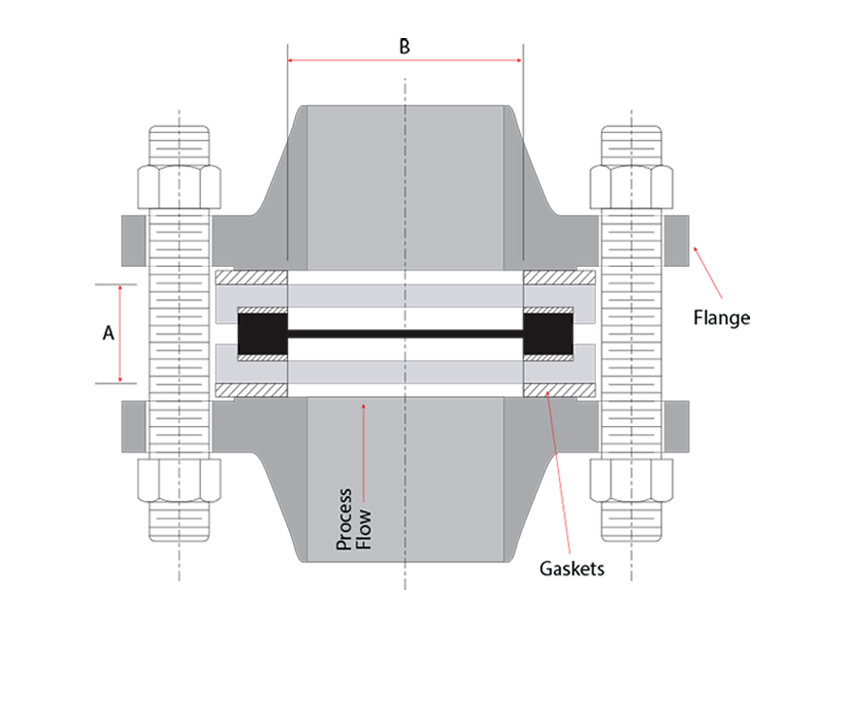

| Disk Size | Burst Pressure | Total Assembly Thickness ‘A’ | |||||||

| psig | barg | 316ss | Graphite | ||||||

|---|---|---|---|---|---|---|---|---|---|

| in | mm | min | max | min | max | in | mm | in | mm |

| 1 | 25 | 10 | 435 | 0.7 | 30 | 1.1 | 28 | 1.1 | 28 |

| 1.5 | 40 | 7 | 290 | 0.5 | 20 | 1.1 | 28 | 1.2 | 31 |

| 2 | 50 | 3 | 217 | 0.2 | 15 | 1.1 | 28 | 1.3 | 32 |

| 2.5 | 65 | 3 | 174 | 0.2 | 12 | 1.2 | 30 | 1.5 | 37 |

| 3 | 80 | 2.2 | 145 | 0.2 | 10 | 1.4 | 35 | 1.7 | 42 |

| 4 | 100 | 2.2 | 116 | 0.2 | 8 | 1.5 | 37 | 1.9 | 47 |

| 5 | 125 | 1.5 | 87 | 0.1 | 6 | 1.6 | 40 | 1.9 | 47 |

| 6 | 150 | 1 | 72 | 0.1 | 5 | 1.7 | 44 | 1.9 | 47 |

| 8 | 200 | 1 | 58 | 0.1 | 4 | 2 | 50 | 2.4 | 61 |

| 10 | 250 | 1 | 43 | 0.1 | 3 | 2 | 53 | 2.7 | 68 |

| 12 | 300 | 1 | 36 | 0.1 | 3 | 2.4 | 61 | 3 | 76 |

| 14 | 350 | 1 | 29 | 0.1 | 2 | 2.5 | 63 | 3.2 | 80 |

| 16 | 400 | 1 | 21 | 0.1 | 2 | 2.8 | 70 | 3.3 | 83 |

| 18 | 450 | 1 | 21 | 0.1 | 2 | 3 | 77 | 3.6 | 92 |

| 20 | 500 | 1 | 17 | 0.1 | 1 | 3.5 | 88 | 4.1 | 105 |

| 24 | 600 | 1 | 17 | 0.1 | 1 | 3.7 | 93 | 4.4 | 111 |

Burst Tolerance

| Marked Burst Pressure | Burst Tolerance |

|---|---|

| < 1 psig (0.07 barg) | -0/+0.75 psig (0/0.05 barg) |

| 1 – 15 psig (0.07 barg < 1.03 barg) | ± 0.75 psig (0.05 barg) |

| > 15 psig (1.03 barg) | ± 5% |

Example: If a Saf-T-Graf RE type disk is ordered with a 29 psig (2 bar) burst pressure, it will burst between 27.5 psig (1.9 bar) and 30.5 psig (2.1 bar). For reduced tolerances contact BS&B.

Armored Option

An armoring ring is recommended for all graphite disks for added safety eliminating premature bursting of the disk due to uneven or excessive torquing of the pipe flange studs. Armoring minimizes the probability of damage in transit and during installation. Carbon steel armor is standard with stainless steel offered as an option. Armoring is standard in the following sizes and with burst pressures in excess of the following:

| Size | Burst Pressure | ||

| in | mm | psig | barg |

|---|---|---|---|

| 1 | 25 | 130 | 8.9 |

| 1.5 | 40 | 115 | 7.9 |

| 2 | 50 | 100 | 6.9 |

| 2.5 | 65 | 93 | 6.4 |

| 3 | 80 | 85 | 5.9 |

| 4 | 100 | 70 | 4.8 |

| 5 | 125 | 60 | 4.1 |

| 6 | 150 | 50 | 3.4 |

| 8 | 200 | 40 | 2.8 |

| 10 | 250 | 25 | 2.1 |

| 12-24 | 300-600 | 25 | 1.7 |

Sizes & Pressures

RE™, REL™, REV™ Disk Specifications Minimum/Maximum Pressure with Rating at 72° (22°C)

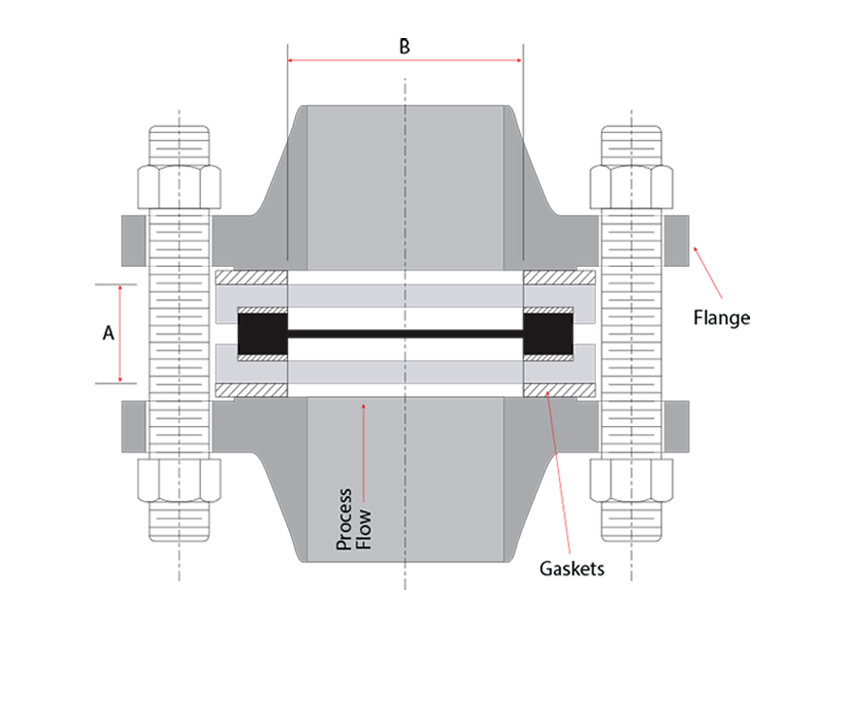

| Disk Size | Burst Pressure | Total Assembly Thickness ‘A’ | |||||||

| psig | barg | 316ss | Graphite | ||||||

|---|---|---|---|---|---|---|---|---|---|

| in | mm | min | max | min | max | in | mm | in | mm |

| 1 | 25 | 10 | 435 | 0.7 | 30 | 1.1 | 28 | 1.1 | 28 |

| 1.5 | 40 | 7 | 290 | 0.5 | 20 | 1.1 | 28 | 1.2 | 31 |

| 2 | 50 | 3 | 217 | 0.2 | 15 | 1.1 | 28 | 1.3 | 32 |

| 2.5 | 65 | 3 | 174 | 0.2 | 12 | 1.2 | 30 | 1.5 | 37 |

| 3 | 80 | 2.2 | 145 | 0.2 | 10 | 1.4 | 35 | 1.7 | 42 |

| 4 | 100 | 2.2 | 116 | 0.2 | 8 | 1.5 | 37 | 1.9 | 47 |

| 5 | 125 | 1.5 | 87 | 0.1 | 6 | 1.6 | 40 | 1.9 | 47 |

| 6 | 150 | 1 | 72 | 0.1 | 5 | 1.7 | 44 | 1.9 | 47 |

| 8 | 200 | 1 | 58 | 0.1 | 4 | 2 | 50 | 2.4 | 61 |

| 10 | 250 | 1 | 43 | 0.1 | 3 | 2 | 53 | 2.7 | 68 |

| 12 | 300 | 1 | 36 | 0.1 | 3 | 2.4 | 61 | 3 | 76 |

| 14 | 350 | 1 | 29 | 0.1 | 2 | 2.5 | 63 | 3.2 | 80 |

| 16 | 400 | 1 | 21 | 0.1 | 2 | 2.8 | 70 | 3.3 | 83 |

| 18 | 450 | 1 | 21 | 0.1 | 2 | 3 | 77 | 3.6 | 92 |

| 20 | 500 | 1 | 17 | 0.1 | 1 | 3.5 | 88 | 4.1 | 105 |

| 24 | 600 | 1 | 17 | 0.1 | 1 | 3.7 | 93 | 4.4 | 111 |

Burst Tolerance

| Marked Burst Pressure | Burst Tolerance |

|---|---|

| < 1 psig (0.07 barg) | -0/+0.75 psig (0/0.05 barg) |

| 1 – 15 psig (0.07 barg < 1.03 barg) | ± 0.75 psig (0.05 barg) |

| > 15 psig (1.03 barg) | ± 5% |

Example: If a Saf-T-Graf RE type disk is ordered with a 29 psig (2 bar) burst pressure, it will burst between 27.5 psig (1.9 bar) and 30.5 psig (2.1 bar). For reduced tolerances contact BS&B.

Armored Option

An armoring ring is recommended for all graphite disks for added safety eliminating premature bursting of the disk due to uneven or excessive torquing of the pipe flange studs. Armoring minimizes the probability of damage in transit and during installation. Carbon steel armor is standard with stainless steel offered as an option. Armoring is standard in the following sizes and with burst pressures in excess of the following:

| Size | Burst Pressure | ||

| in | mm | psig | barg |

|---|---|---|---|

| 1 | 25 | 130 | 8.9 |

| 1.5 | 40 | 115 | 7.9 |

| 2 | 50 | 100 | 6.9 |

| 2.5 | 65 | 93 | 6.4 |

| 3 | 80 | 85 | 5.9 |

| 4 | 100 | 70 | 4.8 |

| 5 | 125 | 60 | 4.1 |

| 6 | 150 | 50 | 3.4 |

| 8 | 200 | 40 | 2.8 |

| 10 | 250 | 25 | 2.1 |

| 12-24 | 300-600 | 25 | 1.7 |