HiLo™

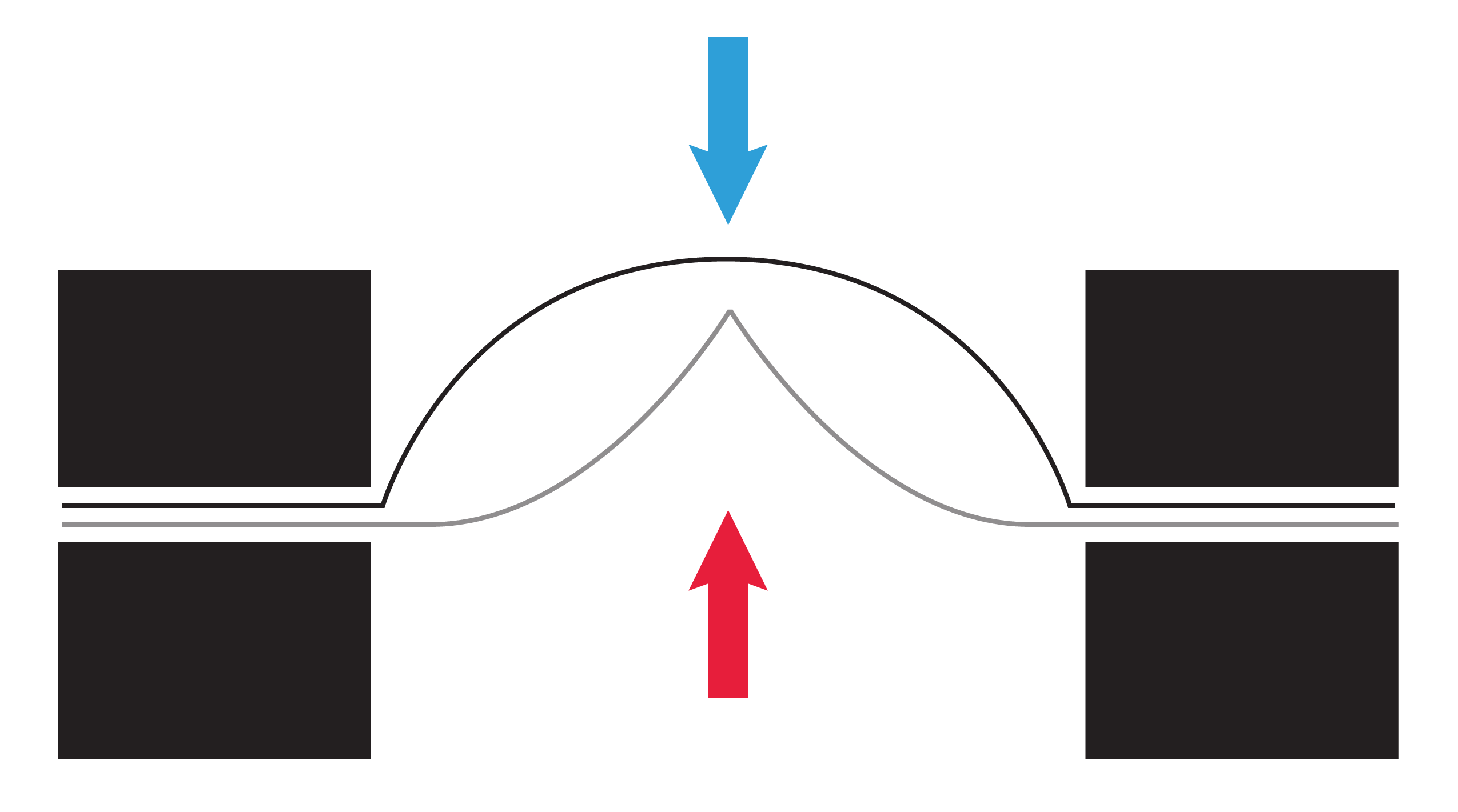

高温超低圧両方向作動破裂板

性能

お問い合わせはこちらから

Sizes & Pressures

Fluoropolymer Seal Burst Pressure Range from 50°F to 150°F (10°C to 65°C)| Disk Size | Low Pressure Direction Burst Pressure | High Pressure Direction Burst Pressure | |||||||

| WC inches | mbar | psi | bar | ||||||

| in | mm | min | max | min | max | min | max | min | max |

|---|---|---|---|---|---|---|---|---|---|

| 2 | 50 | 10 | 51 | 25 | 127 | 11 | 28 | 0.8 | 1.9 |

| 3 | 80 | 6 | 36 | 15 | 90 | 8 | 28 | 0.6 | 1.9 |

| 4 | 100 | 5 | 28 | 12.5 | 70 | 7 | 28 | 0.5 | 1.9 |

| 6 | 150 | 6 | 19 | 15 | 47 | 4 | 22 | 0.3 | 1.5 |

| 8 | 200 | 5 | 15 | 12.5 | 37 | 3 | 22 | 0.2 | 1.5 |

Chemfilm® DF2919 Seal Burst Pressure Range from 50°F to 400°F (10°C to 204°C)

| Disk Size | Low Pressure Direction Burst Pressure | High Pressure Direction Burst Pressure | |||||||

| WC inches | mbar | psi | bar | ||||||

| in | mm | min | max | min | max | min | max | min | max |

|---|---|---|---|---|---|---|---|---|---|

| 2 | 50 | 18 | 300 | 45 | 747 | 39 | 75 | 2.7 | 5.2 |

| 3 | 80 | 7 | 300 | 17.5 | 747 | 28 | 75 | 1.9 | 5.2 |

| 4 | 100 | 5 | 300 | 12.5 | 747 | 22 | 75 | 1.5 | 5.2 |

| 6 | 150 | 6 | 300 | 15 | 747 | 15 | 75 | 1 | 5.2 |

| 8 | 200 | 5 | 300 | 12.5 | 747 | 12 | 75 | 0.08 | 5.2 |

Burst Tolerance

Hi direction burst tolerance| Specified Burst Pressure | Burst Tolerance | |

| psig | barg | |

|---|---|---|

| > 4 to 9 | > 0.3 to 0.6 | ± 20% |

| > 9 to 13 | > 0.6 to 0.9 | ± 15% |

| > 13 to 18 | > 0.9 to 1.2 | ± 10% |

| >18 to 25 | > 1.2 to 1.7 | ± 7% |

| > 25 | > 1.7 | ± 5psig |

| Specified Burst Pressure | Burst Tolerance | |

| inch WG | mbar | |

|---|---|---|

| < 8 | < 2.76 | ± 1.5 in WG (3.8mbar) |

| > 8 | > 2.76 | ± 20% |

Hi direction manufacturing design range

| Specified Burst Pressure | Burst Tolerance | |

| psig | barg | |

|---|---|---|

| ≤ 40 | ≤ 2.76 | ± 2psig (0.1bar) |

| > 40 | > 2.76 | – 10% |

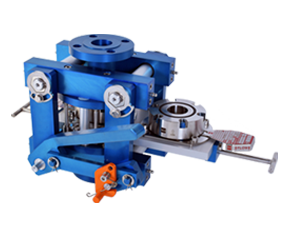

Safety Heads

Sensors

Accessories

BS&B supplies many of the accessories required to safely and conveniently install our overpressure relief devices and complementary products. Through our professional team and global network of sales engineers and procurement personnel, we are able to provide the highest quality accessory products to meet your installation requirements.

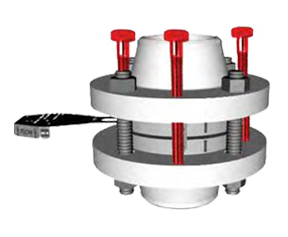

Saf-T-Change Quick Disk Replacement (QDR)

After activation, the replacement disk is quickly slid into place. Saving hours of lost production due to blown rupture disks.

Tell-Tale Assemblies & Excess Flow Valves/Gauges

A gauge tap in the outlet flange of the safety head may be considered when the safety head is installed in a vertical position.

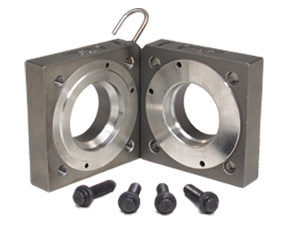

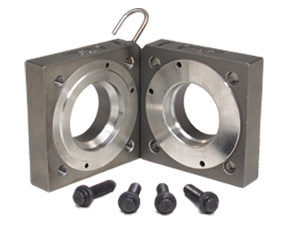

Spare Safety Heads & Cap Screws

Jackscrews

When activated, the jackscrews effectively separate the flanges, providing adequate clearance to remove or insert a safety head and external gaskets.

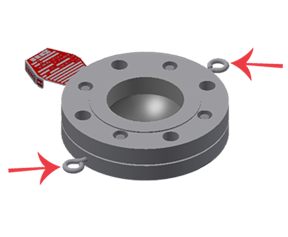

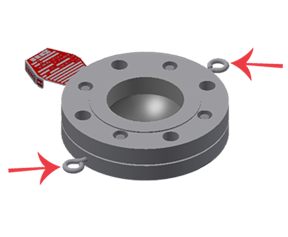

Lifting Lug Eye Bolts

Eye bolts are recommended when weight and/or accessibility is a factor in lifting safety heads.

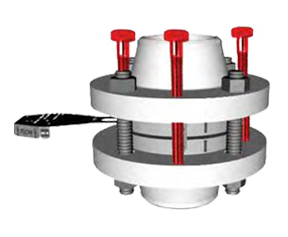

Baffle Plate

When a safety head is free-vented to atmosphere, a baffle plate may be considered to disperse overpressure and absorb recoil.

Sizes & Pressures

Fluoropolymer Seal Burst Pressure Range from 50°F to 150°F (10°C to 65°C)| Disk Size | Low Pressure Direction Burst Pressure | High Pressure Direction Burst Pressure | |||||||

| WC inches | mbar | psi | bar | ||||||

| in | mm | min | max | min | max | min | max | min | max |

|---|---|---|---|---|---|---|---|---|---|

| 2 | 50 | 10 | 51 | 25 | 127 | 11 | 28 | 0.8 | 1.9 |

| 3 | 80 | 6 | 36 | 15 | 90 | 8 | 28 | 0.6 | 1.9 |

| 4 | 100 | 5 | 28 | 12.5 | 70 | 7 | 28 | 0.5 | 1.9 |

| 6 | 150 | 6 | 19 | 15 | 47 | 4 | 22 | 0.3 | 1.5 |

| 8 | 200 | 5 | 15 | 12.5 | 37 | 3 | 22 | 0.2 | 1.5 |

Chemfilm® DF2919 Seal Burst Pressure Range from 50°F to 400°F (10°C to 204°C)

| Disk Size | Low Pressure Direction Burst Pressure | High Pressure Direction Burst Pressure | |||||||

| WC inches | mbar | psi | bar | ||||||

| in | mm | min | max | min | max | min | max | min | max |

|---|---|---|---|---|---|---|---|---|---|

| 2 | 50 | 18 | 300 | 45 | 747 | 39 | 75 | 2.7 | 5.2 |

| 3 | 80 | 7 | 300 | 17.5 | 747 | 28 | 75 | 1.9 | 5.2 |

| 4 | 100 | 5 | 300 | 12.5 | 747 | 22 | 75 | 1.5 | 5.2 |

| 6 | 150 | 6 | 300 | 15 | 747 | 15 | 75 | 1 | 5.2 |

| 8 | 200 | 5 | 300 | 12.5 | 747 | 12 | 75 | 0.08 | 5.2 |

Burst Tolerance

Hi direction burst tolerance| Specified Burst Pressure | Burst Tolerance | |

| psig | barg | |

|---|---|---|

| > 4 to 9 | > 0.3 to 0.6 | ± 20% |

| > 9 to 13 | > 0.6 to 0.9 | ± 15% |

| > 13 to 18 | > 0.9 to 1.2 | ± 10% |

| >18 to 25 | > 1.2 to 1.7 | ± 7% |

| > 25 | > 1.7 | ± 5psig |

| Specified Burst Pressure | Burst Tolerance | |

| inch WG | mbar | |

|---|---|---|

| < 8 | < 2.76 | ± 1.5 in WG (3.8mbar) |

| > 8 | > 2.76 | ± 20% |

Hi direction manufacturing design range

| Specified Burst Pressure | Burst Tolerance | |

| psig | barg | |

|---|---|---|

| ≤ 40 | ≤ 2.76 | ± 2psig (0.1bar) |

| > 40 | > 2.76 | – 10% |

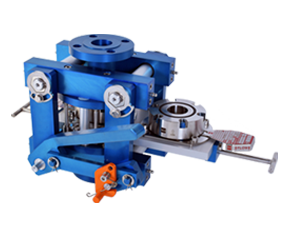

Safety Heads

Sensors

Accessories

BS&B supplies many of the accessories required to safely and conveniently install our overpressure relief devices and complementary products. Through our professional team and global network of sales engineers and procurement personnel, we are able to provide the highest quality accessory products to meet your installation requirements.

Saf-T-Change Quick Disk Replacement (QDR)

After activation, the replacement disk is quickly slid into place. Saving hours of lost production due to blown rupture disks.

Tell-Tale Assemblies & Excess Flow Valves/Gauges

A gauge tap in the outlet flange of the safety head may be considered when the safety head is installed in a vertical position.

Spare Safety Heads & Cap Screws

Jackscrews

When activated, the jackscrews effectively separate the flanges, providing adequate clearance to remove or insert a safety head and external gaskets.

Lifting Lug Eye Bolts

Eye bolts are recommended when weight and/or accessibility is a factor in lifting safety heads.

Baffle Plate

When a safety head is free-vented to atmosphere, a baffle plate may be considered to disperse overpressure and absorb recoil.