ECR™

タンクアプリケーション用低圧破裂板

性能

お問い合わせはこちらから

Sizes & Pressures

ECR™ Disk Specifications Minimum Pressure (determined by disk type and gasket material)| Disk Size | Buna N, Viton, silicone and EPDM gaskets | Fluoropolymer gaskets (process side for ECR only) | |||||||||||

| in | mm | ECR and V/ECR | ECV and V/ECV | ECR-S and V-ECR-S | ECV-S and V/ECV-S | ECR and V/ECR | ECV and V/ECV | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | ||

| 1 | 25 | 2 | 0.1 | 8 | 0.6 | 6.5 | 0.5 | 8 | 0.6 | 6.5 | 0.5 | 12 | 0.8 |

| 1.5 | 40 | 2 | 0.1 | 5 | 0.3 | 4.5 | 0.3 | 5 | 0.3 | 4.5 | 0.3 | 7 | 0.5 |

| 2 | 50 | 2 | 0.1 | 3 | 0.2 | 3 | 0.2 | 3 | 0.2 | 3 | 0.2 | 5 | 0.4 |

| 3 | 80 | 1 | 0.1 | 2 | 0.1 | 2 | 0.1 | 2 | 0.1 | 2 | 0.1 | 5 | 0.4 |

| 4 | 100 | 1 | 0.1 | 2 | 0.1 | 2 | 0.1 | 2 | 0.1 | 2 | 0.1 | 4 | 0.2 |

| 6 | 150 | 1 | 0.1 | 2 | 0.1 | 2 | 0.1 | 2 | 0.1 | 2 | 0.1 | 4 | 0.2 |

| 8-10 | 200-250 | 1 | 0.1 | 1.5 | 0.1 | 1.5 | 0.1 | 1.5 | 0.1 | 1.5 | 0.1 | 2 | 0.1 |

| 12-24 | 300-600 | 1 | 0.1 | – | – | 1 | 0.1 | – | – | 1 | 0.1 | – | – |

ECR™ Disk Specifications Maximum Pressure (determined by disk type and gasket material)

| Disk Size | Buna N gaskets | Viton®, silicone and EPDM gaskets | |||||||||||||||

| in | mm | ECR and V/ECR | ECV and V/ECV | ECR-S and V-ECR-S | ECV-S and V/ECV-S | ECR and V/ECR | ECV and V/ECV | ECR-S and V-ECR-S | ECV-S and V/ECV-S | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | ||

| 1 | 25 | 100 | 6.9 | 100 | 6.9 | 100 | 6.9 | 100 | 6.9 | 25 | 2 | 25 | 2 | 25 | 2 | 25 | 2 |

| 1.5 | 40 | 80 | 5.5 | 80 | 6 | 80 | 5.5 | 80 | 6 | 25 | 2 | 25 | 2 | 25 | 2 | 25 | 2 |

| 2 | 50 | 80 | 5.5 | 80 | 6 | 80 | 5.5 | 80 | 6 | 25 | 2 | 25 | 2 | 25 | 2 | 25 | 2 |

| 3 | 80 | 50 | 3.5 | 50 | 3.5 | 50 | 3.5 | 50 | 3.5 | 25 | 2 | 25 | 2 | 25 | 2 | 25 | 2 |

| 4 | 100 | 50 | 3.5 | 50 | 3.5 | 50 | 3.5 | 50 | 3.5 | 25 | 2 | 25 | 2 | 25 | 2 | 25 | 2 |

| 6 | 150 | 50 | 3.5 | 50 | 3.5 | 50 | 3.5 | 50 | 3.5 | 25 | 2 | 25 | 2 | 25 | 2 | 25 | 2 |

| 8-10 | 200-250 | 15 | 1 | 15 | 1 | 15 | 1 | 15 | 1 | 15 | 1 | 15 | 1 | 15 | 1 | 15 | 1 |

| 12-24 | 300-600 | 15 | 1 | – | – | 15 | 1 | – | – | 15 | 1 | – | – | 15 | 1 | – | – |

Burst Tolerance

| Marked Burst Pressure | Burst Tolerance |

|---|---|

| ≤ 40 psig (2.76 barg) | ± 2 psig (0.138 barg) |

| > 40 psig (2.76 barg) | ± 5% |

Accessories

BS&B supplies many of the accessories required to safely and conveniently install our overpressure relief devices and complementary products. Through our professional team and global network of sales engineers and procurement personnel, we are able to provide the highest quality accessory products to meet your installation requirements.

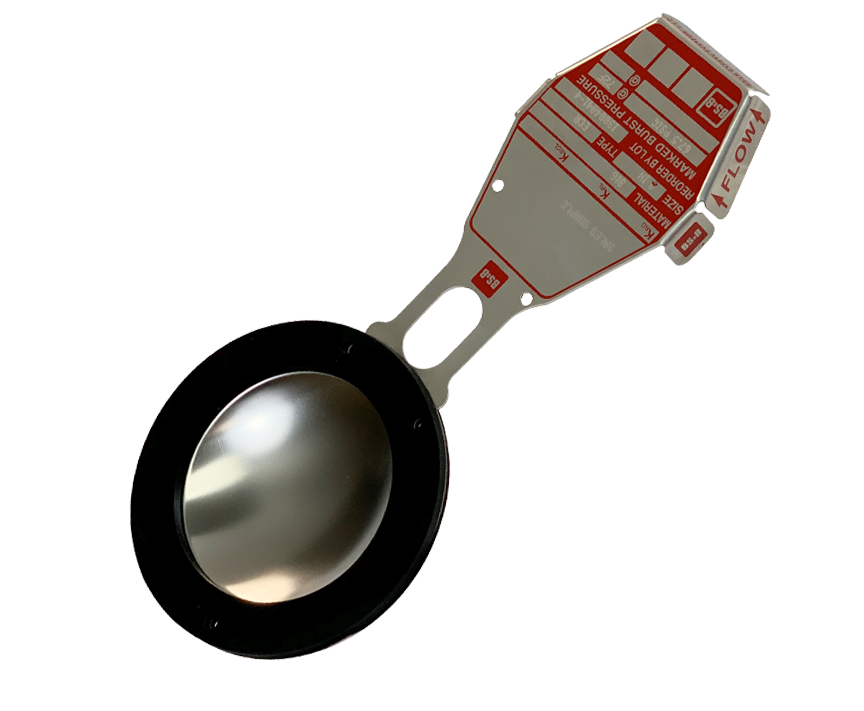

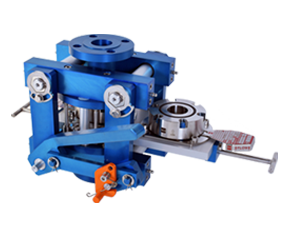

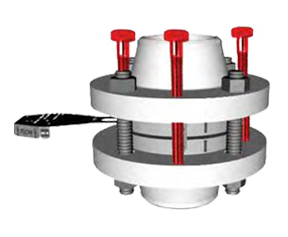

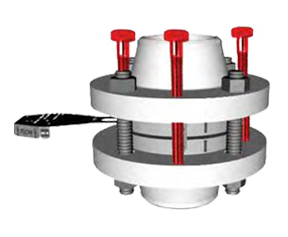

Saf-T-Change Quick Disk Replacement (QDR)

After activation, the replacement disk is quickly slid into place. Saving hours of lost production due to blown rupture disks.

Tell-Tale Assemblies & Excess Flow Valves/Gauges

A gauge tap in the outlet flange of the safety head may be considered when the safety head is installed in a vertical position.

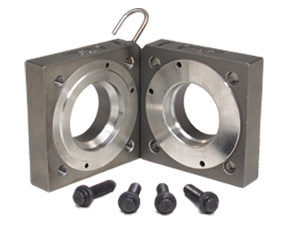

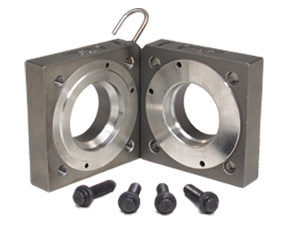

Spare Safety Heads & Cap Screws

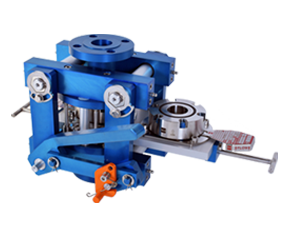

Jackscrews

When activated, the jackscrews effectively separate the flanges, providing adequate clearance to remove or insert a safety head and external gaskets.

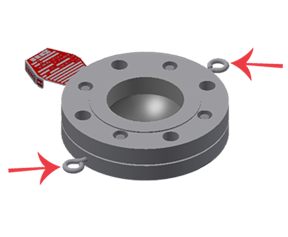

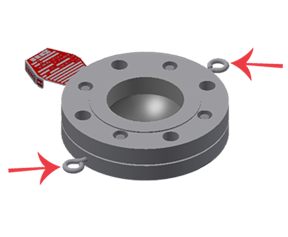

Lifting Lug Eye Bolts

Eye bolts are recommended when weight and/or accessibility is a factor in lifting safety heads.

Baffle Plate

When a safety head is free-vented to atmosphere, a baffle plate may be considered to disperse overpressure and absorb recoil.

Product Literature

Sizes & Pressures

ECR™ Disk Specifications Minimum Pressure (determined by disk type and gasket material)| Disk Size | Buna N, Viton, silicone and EPDM gaskets | Fluoropolymer gaskets (process side for ECR only) | |||||||||||

| in | mm | ECR and V/ECR | ECV and V/ECV | ECR-S and V-ECR-S | ECV-S and V/ECV-S | ECR and V/ECR | ECV and V/ECV | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | ||

| 1 | 25 | 2 | 0.1 | 8 | 0.6 | 6.5 | 0.5 | 8 | 0.6 | 6.5 | 0.5 | 12 | 0.8 |

| 1.5 | 40 | 2 | 0.1 | 5 | 0.3 | 4.5 | 0.3 | 5 | 0.3 | 4.5 | 0.3 | 7 | 0.5 |

| 2 | 50 | 2 | 0.1 | 3 | 0.2 | 3 | 0.2 | 3 | 0.2 | 3 | 0.2 | 5 | 0.4 |

| 3 | 80 | 1 | 0.1 | 2 | 0.1 | 2 | 0.1 | 2 | 0.1 | 2 | 0.1 | 5 | 0.4 |

| 4 | 100 | 1 | 0.1 | 2 | 0.1 | 2 | 0.1 | 2 | 0.1 | 2 | 0.1 | 4 | 0.2 |

| 6 | 150 | 1 | 0.1 | 2 | 0.1 | 2 | 0.1 | 2 | 0.1 | 2 | 0.1 | 4 | 0.2 |

| 8-10 | 200-250 | 1 | 0.1 | 1.5 | 0.1 | 1.5 | 0.1 | 1.5 | 0.1 | 1.5 | 0.1 | 2 | 0.1 |

| 12-24 | 300-600 | 1 | 0.1 | – | – | 1 | 0.1 | – | – | 1 | 0.1 | – | – |

ECR™ Disk Specifications Maximum Pressure (determined by disk type and gasket material)

| Disk Size | Buna N gaskets | Viton®, silicone and EPDM gaskets | |||||||||||||||

| in | mm | ECR and V/ECR | ECV and V/ECV | ECR-S and V-ECR-S | ECV-S and V/ECV-S | ECR and V/ECR | ECV and V/ECV | ECR-S and V-ECR-S | ECV-S and V/ECV-S | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | ||

| 1 | 25 | 100 | 6.9 | 100 | 6.9 | 100 | 6.9 | 100 | 6.9 | 25 | 2 | 25 | 2 | 25 | 2 | 25 | 2 |

| 1.5 | 40 | 80 | 5.5 | 80 | 6 | 80 | 5.5 | 80 | 6 | 25 | 2 | 25 | 2 | 25 | 2 | 25 | 2 |

| 2 | 50 | 80 | 5.5 | 80 | 6 | 80 | 5.5 | 80 | 6 | 25 | 2 | 25 | 2 | 25 | 2 | 25 | 2 |

| 3 | 80 | 50 | 3.5 | 50 | 3.5 | 50 | 3.5 | 50 | 3.5 | 25 | 2 | 25 | 2 | 25 | 2 | 25 | 2 |

| 4 | 100 | 50 | 3.5 | 50 | 3.5 | 50 | 3.5 | 50 | 3.5 | 25 | 2 | 25 | 2 | 25 | 2 | 25 | 2 |

| 6 | 150 | 50 | 3.5 | 50 | 3.5 | 50 | 3.5 | 50 | 3.5 | 25 | 2 | 25 | 2 | 25 | 2 | 25 | 2 |

| 8-10 | 200-250 | 15 | 1 | 15 | 1 | 15 | 1 | 15 | 1 | 15 | 1 | 15 | 1 | 15 | 1 | 15 | 1 |

| 12-24 | 300-600 | 15 | 1 | – | – | 15 | 1 | – | – | 15 | 1 | – | – | 15 | 1 | – | – |

Burst Tolerance

| Marked Burst Pressure | Burst Tolerance |

|---|---|

| ≤ 40 psig (2.76 barg) | ± 2 psig (0.138 barg) |

| > 40 psig (2.76 barg) | ± 5% |

Accessories

BS&B supplies many of the accessories required to safely and conveniently install our overpressure relief devices and complementary products. Through our professional team and global network of sales engineers and procurement personnel, we are able to provide the highest quality accessory products to meet your installation requirements.

Saf-T-Change Quick Disk Replacement (QDR)

After activation, the replacement disk is quickly slid into place. Saving hours of lost production due to blown rupture disks.

Tell-Tale Assemblies & Excess Flow Valves/Gauges

A gauge tap in the outlet flange of the safety head may be considered when the safety head is installed in a vertical position.

Spare Safety Heads & Cap Screws

Jackscrews

When activated, the jackscrews effectively separate the flanges, providing adequate clearance to remove or insert a safety head and external gaskets.

Lifting Lug Eye Bolts

Eye bolts are recommended when weight and/or accessibility is a factor in lifting safety heads.

Baffle Plate

When a safety head is free-vented to atmosphere, a baffle plate may be considered to disperse overpressure and absorb recoil.

Product Literature

概要

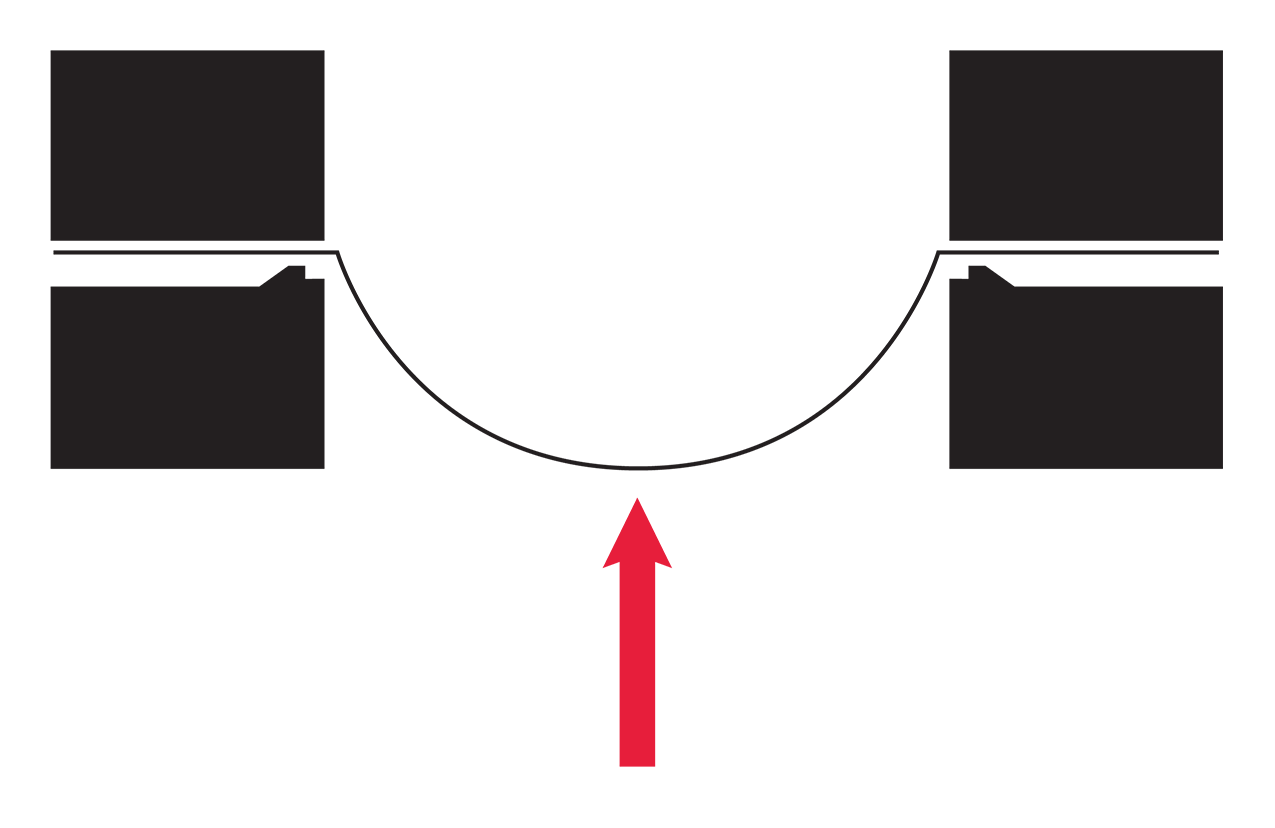

ECR™ 型は運転中圧縮力を受けている反転型破裂板で気体/ベーバー、液体のどれにも適応し圧力解放します。ECR破裂板は、ドームの周縁部にスコア溝の加工された設計になっています。アッセンブリー型ホルダーによりガスケットが作動し、スコア溝がシールされる構造です。反転型破裂板のスナップアクション技術により最低設定圧力を実現することで、脆弱な溝付き複合破裂板設計を選択する必要がなくなります。