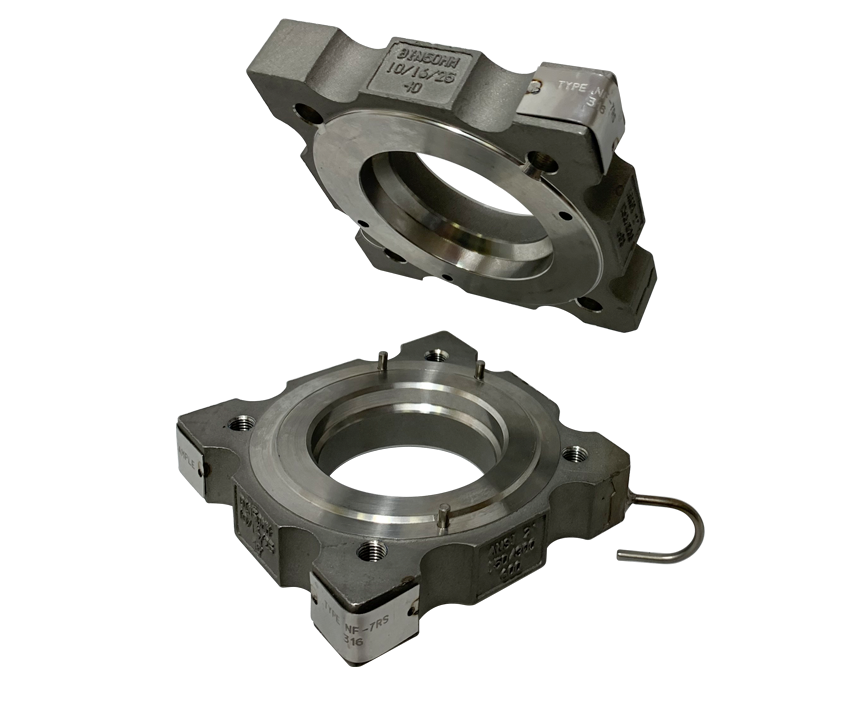

NF-7RS™ホルダー

プリトルクホルダー

性能

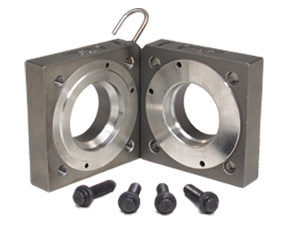

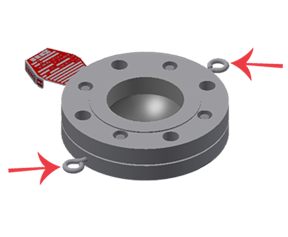

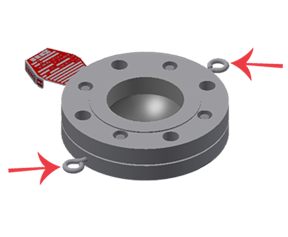

- フランジのボルトサークル内に収まり、取り付け、取り外しが容易なインサートタイプのホルダー

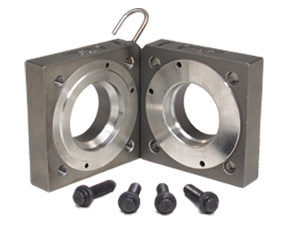

- 事前にトルクをかけられたキャップスクリューが、コンパニオン・フランジ・ボルトとは別に独立してホルダー内のラプチャー・ディスクをクランプするため、定期メンテナンス時の取り外し、検査、および再取り付けが可能

- J ボルトは、プロセス側フランジの外周に開けられた穴と接合することにより、ホルダーが必要な方向に確実に取り付けられるようにします

- ホルダー内の位置決めピンが破裂板の位置決めホールと接合する事により、破裂板のセンタリングと正しい取付け方向を確保

- セーフティヘッドの側面に刻印されているフロー矢印は、正しいフロー方向を示します

- ホルダー内側座面に独自の「バイトシール」を施しており、破裂板とホルダーのプロセス側の間のシール性を最適化し、10^-6cc/s He 以上の気密性を実現

- 入口または出口のいずれかにオプションでタップ追加工が可能で、監視デバイスやセンサーの設置が可能

- フランジ付き配管接続に使用。レイズドフェイス、リングジョイント、その他複数のフランジ定格および配管規格に対応した設計

- ラプチャーディスクのドーム部は、配管システムに設置される際の損傷を避けるため、ホルダー内で完全に保護されています

- トルク耐性のあるバージョンも利用可能、NF-7RS-TR をご指定下さい

- ダブルディスクアセンブリーとしても利用可能

お問い合わせはこちらから

Sizes & Pressures

NF-7RS™ Safety Head Dimensions

| Disk Size | Safety Head Flange Rating | Overall Height | Outside Dimensions | Shape | |||||

| in | mm | ANSI | DIN | JIS | in | mm | in | mm | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 25 | 150 | 6 | – | 1.5 | 38 | 2.6 | 67 | square |

| 300/600 | 10/16/25/40 | 10/16/20/30/40 | 1.5 | 38 | 2.9 | 73 | square | ||

| 1.5 | 40 | 150 | – | 10/16/20 | 1.7 | 43 | 3.4 | 86 | square |

| 300/600 | 10/16/25/40 | 30/40 | 1.7 | 43 | 3.7 | 95 | square | ||

| 2 | 50 | 150/300/600 | 10/16/25/40 | 10/16/20/30/40 | 1.9 | 48 | 4.1 | 104 | square |

| 3 | 80 | 150/300/600 | 10/16/25/40 | 10/16/20/40 | 2.2 | 55 | 5.2 | 133 | square |

| – | – | 10 | 2.2 | 55 | 5.2 | 132 | square | ||

| 4 | 100 | 150/300 | 10/16/25/40 | 16/20/30/40 | 2.9 | 73 | 6.2 | 158 | square |

| – | – | 10 | 2.9 | 73 | 6.2 | 158 | square | ||

| 600 | – | – | 2.6 | 65 | 7.6 | 192 | round | ||

| 6 | 150 | 150/300 | 10/16/25/40 | 10/30/40 | 3.6 | 92 | 9.8 | 248 | round |

| 600 | – | – | 4.5 | 114 | 10.4 | 264 | round | ||

| 8 | 200 | 150/300 | – | – | 3.8 | 97 | 12.0 | 305 | round |

| 10 | 250 | 150/300 | – | – | 4.3 | 110 | 14.1 | 359 | round |

| 12 | 300 | 150 | – | – | 4.8 | 121 | 16.0 | 406 | round |

| 300 | – | – | 5.3 | 133 | 16.5 | 419 | round | ||

| 14 | 350 | 150 | – | – | 5.3 | 133 | 17.8 | 451 | round |

| 300 | – | – | 5.9 | 149 | 19.6 | 483 | round | ||

| 16 | 400 | 150 | – | – | 6.4 | 162 | 20.1 | 511 | round |

| 300 | – | – | 7.1 | 181 | 21.1 | 536 | round | ||

| 18 | 450 | 150 | – | – | 7.4 | 187 | 22.8 | 578 | round |

| 300 | – | – | 7.9 | 200 | 23.4 | 594 | round | ||

| 20 | 500 | 150 | – | – | 8.4 | 241 | 24.8 | 629 | round |

| 300 | – | – | 8.6 | 219 | 25.6 | 651 | round | ||

| 24 | 600 | 150 | – | – | 10.3 | 260 | 29.5 | 749 | round |

| 300 | – | – | 10.8 | 273 | 30.4 | 772 | round | ||

Rupture Disks

Standard Materials

316 stainless steel and carbon steel.

Also available Monel® alloy 400, Inconel® alloy 600, Hastelloy® alloy C and C-276, aluminum, and titanium.

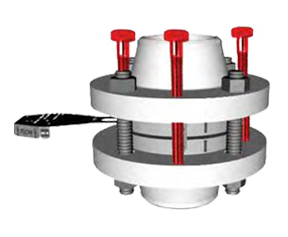

Torque Resistant Safety Head Option

The Type TR™ Series torque resistant safety head option offers the identical performance and flow characteristics valued from standard BS&B safety heads. The only difference – the TR Series Safety Heads are designed with a wider seating surface to be used with metal spiral wound gaskets at the flange. This distinct safety feature protects rupture disks from situations where plant personnel may overtorque rupture disks within piping systems.

Because of the wider seating surface of the TR Series Safety Head, the load is distributed over a much broader area reducing the influence of excessive torque transmitted to the disk.

Accessories

BS&B supplies many of the accessories required to safely and conveniently install our overpressure relief devices and complementary products. Through our professional team and global network of sales engineers and procurement personnel, we are able to provide the highest quality accessory products to meet your installation requirements.

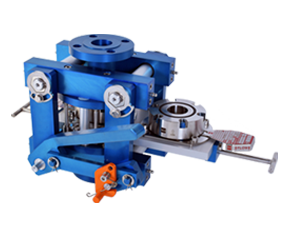

Saf-T-Change Quick Disk Replacement (QDR)

After activation, the replacement disk is quickly slid into place. Saving hours of lost production due to blown rupture disks.

Tell-Tale Assemblies & Excess Flow Valves/Gauges

A gauge tap in the outlet flange of the safety head may be considered when the safety head is installed in a vertical position.

Spare Safety Heads & Cap Screws

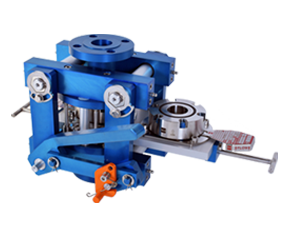

Jackscrews

When activated, the jackscrews effectively separate the flanges, providing adequate clearance to remove or insert a safety head and external gaskets.

Lifting Lug Eye Bolts

Eye bolts are recommended when weight and/or accessibility is a factor in lifting safety heads.

Baffle Plate

When a safety head is free-vented to atmosphere, a baffle plate may be considered to disperse overpressure and absorb recoil.

Sizes & Pressures

NF-7RS™ Safety Head Dimensions

| Disk Size | Safety Head Flange Rating | Overall Height | Outside Dimensions | Shape | |||||

| in | mm | ANSI | DIN | JIS | in | mm | in | mm | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 25 | 150 | 6 | – | 1.5 | 38 | 2.6 | 67 | square |

| 300/600 | 10/16/25/40 | 10/16/20/30/40 | 1.5 | 38 | 2.9 | 73 | square | ||

| 1.5 | 40 | 150 | – | 10/16/20 | 1.7 | 43 | 3.4 | 86 | square |

| 300/600 | 10/16/25/40 | 30/40 | 1.7 | 43 | 3.7 | 95 | square | ||

| 2 | 50 | 150/300/600 | 10/16/25/40 | 10/16/20/30/40 | 1.9 | 48 | 4.1 | 104 | square |

| 3 | 80 | 150/300/600 | 10/16/25/40 | 10/16/20/40 | 2.2 | 55 | 5.2 | 133 | square |

| – | – | 10 | 2.2 | 55 | 5.2 | 132 | square | ||

| 4 | 100 | 150/300 | 10/16/25/40 | 16/20/30/40 | 2.9 | 73 | 6.2 | 158 | square |

| – | – | 10 | 2.9 | 73 | 6.2 | 158 | square | ||

| 600 | – | – | 2.6 | 65 | 7.6 | 192 | round | ||

| 6 | 150 | 150/300 | 10/16/25/40 | 10/30/40 | 3.6 | 92 | 9.8 | 248 | round |

| 600 | – | – | 4.5 | 114 | 10.4 | 264 | round | ||

| 8 | 200 | 150/300 | – | – | 3.8 | 97 | 12.0 | 305 | round |

| 10 | 250 | 150/300 | – | – | 4.3 | 110 | 14.1 | 359 | round |

| 12 | 300 | 150 | – | – | 4.8 | 121 | 16.0 | 406 | round |

| 300 | – | – | 5.3 | 133 | 16.5 | 419 | round | ||

| 14 | 350 | 150 | – | – | 5.3 | 133 | 17.8 | 451 | round |

| 300 | – | – | 5.9 | 149 | 19.6 | 483 | round | ||

| 16 | 400 | 150 | – | – | 6.4 | 162 | 20.1 | 511 | round |

| 300 | – | – | 7.1 | 181 | 21.1 | 536 | round | ||

| 18 | 450 | 150 | – | – | 7.4 | 187 | 22.8 | 578 | round |

| 300 | – | – | 7.9 | 200 | 23.4 | 594 | round | ||

| 20 | 500 | 150 | – | – | 8.4 | 241 | 24.8 | 629 | round |

| 300 | – | – | 8.6 | 219 | 25.6 | 651 | round | ||

| 24 | 600 | 150 | – | – | 10.3 | 260 | 29.5 | 749 | round |

| 300 | – | – | 10.8 | 273 | 30.4 | 772 | round | ||

Rupture Disks

Standard Materials

316 stainless steel and carbon steel.

Also available Monel® alloy 400, Inconel® alloy 600, Hastelloy® alloy C and C-276, aluminum, and titanium.

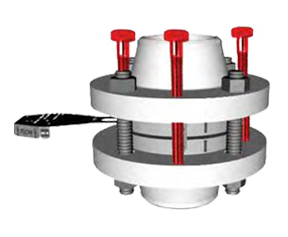

Torque Resistant Safety Head Option

The Type TR™ Series torque resistant safety head option offers the identical performance and flow characteristics valued from standard BS&B safety heads. The only difference – the TR Series Safety Heads are designed with a wider seating surface to be used with metal spiral wound gaskets at the flange. This distinct safety feature protects rupture disks from situations where plant personnel may overtorque rupture disks within piping systems.

Because of the wider seating surface of the TR Series Safety Head, the load is distributed over a much broader area reducing the influence of excessive torque transmitted to the disk.

Accessories

BS&B supplies many of the accessories required to safely and conveniently install our overpressure relief devices and complementary products. Through our professional team and global network of sales engineers and procurement personnel, we are able to provide the highest quality accessory products to meet your installation requirements.

Saf-T-Change Quick Disk Replacement (QDR)

After activation, the replacement disk is quickly slid into place. Saving hours of lost production due to blown rupture disks.

Tell-Tale Assemblies & Excess Flow Valves/Gauges

A gauge tap in the outlet flange of the safety head may be considered when the safety head is installed in a vertical position.

Spare Safety Heads & Cap Screws

Jackscrews

When activated, the jackscrews effectively separate the flanges, providing adequate clearance to remove or insert a safety head and external gaskets.

Lifting Lug Eye Bolts

Eye bolts are recommended when weight and/or accessibility is a factor in lifting safety heads.

Baffle Plate

When a safety head is free-vented to atmosphere, a baffle plate may be considered to disperse overpressure and absorb recoil.