LPS™ Customized Solution

低圧切溝付き反転ドーム形/逆作動破裂板

性能

- 気相液相混合流体兼用

- 最低破裂圧力の90%まで運転可能

- 破片飛散なし、安全弁一次側設置の推奨製品

- ダメージ安全率≤1(ダメージがある場合表示破裂圧力の1倍以下で破裂する)

- 真空耐性あり

- 背圧耐性を指定できます

- ASME “UD”スタンプ対応(製造範囲0%/-5%/-10%選定)

- 圧力機器指令”CE”マーク及びその他国際証書対応 特許6178983, 6321582, 6446653, 6494074申請中

お問い合わせはこちらから

Sizes & Pressures

LPS™ Disk Specifications Minimum/Maximum Pressure with Rating at 72° (22°C)

| Disk Size | Nickel Alloy 200 | Monel® Alloy 400 | Inconel® Alloy 600 | Hastelloy® Alloy C-276 | 316SS | ||||||||||||||||

| in | mm | psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | ||

| 1 | 25 | 15 | 70 | 1.03 | 4.83 | 20 | 70 | 1.38 | 4.83 | 20 | 70 | 1.38 | 4.83 | 15 | 70 | 1.03 | 4.83 | 15 | 70 | 1.03 | 4.83 |

| 1.5 | 40 | 6 | 55 | 0.41 | 3.79 | 10 | 55 | 0.69 | 3.79 | 10 | 55 | 0.69 | 3.79 | 7 | 55 | 0.48 | 3.79 | 6 | 55 | 0.41 | 3.79 |

| 2 | 50 | 5 | 40 | 0.34 | 2.76 | 8 | 40 | 0.55 | 2.76 | 8 | 40 | 0.55 | 2.76 | 6 | 40 | 0.41 | 2.76 | 5 | 40 | 0.34 | 2.76 |

| 3 | 80 | 5 | 35 | 0.34 | 2.41 | 7 | 35 | 0.48 | 2.41 | 7 | 35 | 0.48 | 2.41 | 5 | 35 | 0.34 | 2.41 | 5 | 35 | 0.34 | 2.41 |

| 4 | 100 | 5 | 30 | .034 | 2.06 | 7 | 30 | 0.48 | 2.06 | 7 | 30 | 0.48 | 2.06 | 5 | 30 | 0.34 | 2.06 | 5 | 30 | 0.34 | 2.06 |

| 6 | 150 | 5 | 25 | 0.34 | 1.72 | 7 | 25 | 0.48 | 1.72 | 7 | 25 | 0.48 | 1.72 | 5 | 25 | 0.34 | 1.72 | 5 | 25 | 0.34 | 1.72 |

| 8 | 200 | 5 | 25 | 0.34 | 1.72 | 7 | 25 | 0.48 | 1.72 | 7 | 25 | 0.48 | 1.72 | 5 | 25 | 0.34 | 1.72 | 5 | 25 | 0.34 | 1.72 |

| 10 | 250 | 5 | 25 | 0.34 | 1.72 | 7 | 25 | 0.48 | 1.72 | 7 | 25 | 0.48 | 1.72 | 5 | 25 | 0.34 | 1.72 | 5 | 25 | 0.34 | 1.72 |

| 12 | 300 | 5 | 25 | 0.34 | 1.72 | 7 | 25 | 0.48 | 1.72 | 7 | 25 | 0.48 | 1.72 | 5 | 25 | 0.34 | 1.72 | 5 | 25 | 0.34 | 1.72 |

Consult BS&B for applications where the disk may be rated with a coincident temperature below 300°F (149°C) (176°F (80°C) for Hastelloy) but operated at a higher value. Special processing may be required.

Burst Tolerance

Burst tolerance is the +/- range of pressure over which a rupture disk (bursting disc) can be expected to burst.

| Specified Burst Pressure | Burst Tolerance | |

| psig | barg | |

|---|---|---|

| 28 and higer | 1.9 and higher | ± 5% |

| 20 to 28 | 1.4 to 1.9 | ± 7% |

| 10 to 20 | 0.7 to 1.4 | ± 10% |

| <10 | < 0.7 | ± 15% |

| Alternate: < 40 | < 2.76 | ± 2 psig (0.138 barg) |

Standard Assembly Options

Clamped Assembly

Bolted Assembly

Welded Assembly

This customized ready-to-install design simplifies installation and assures leak tightness with its welded construction.

In Line Assembly

TorqueFit Assembly

Components are assembled together using mechanical methods and application of torque provides leak tight seal

Product Literature

概要

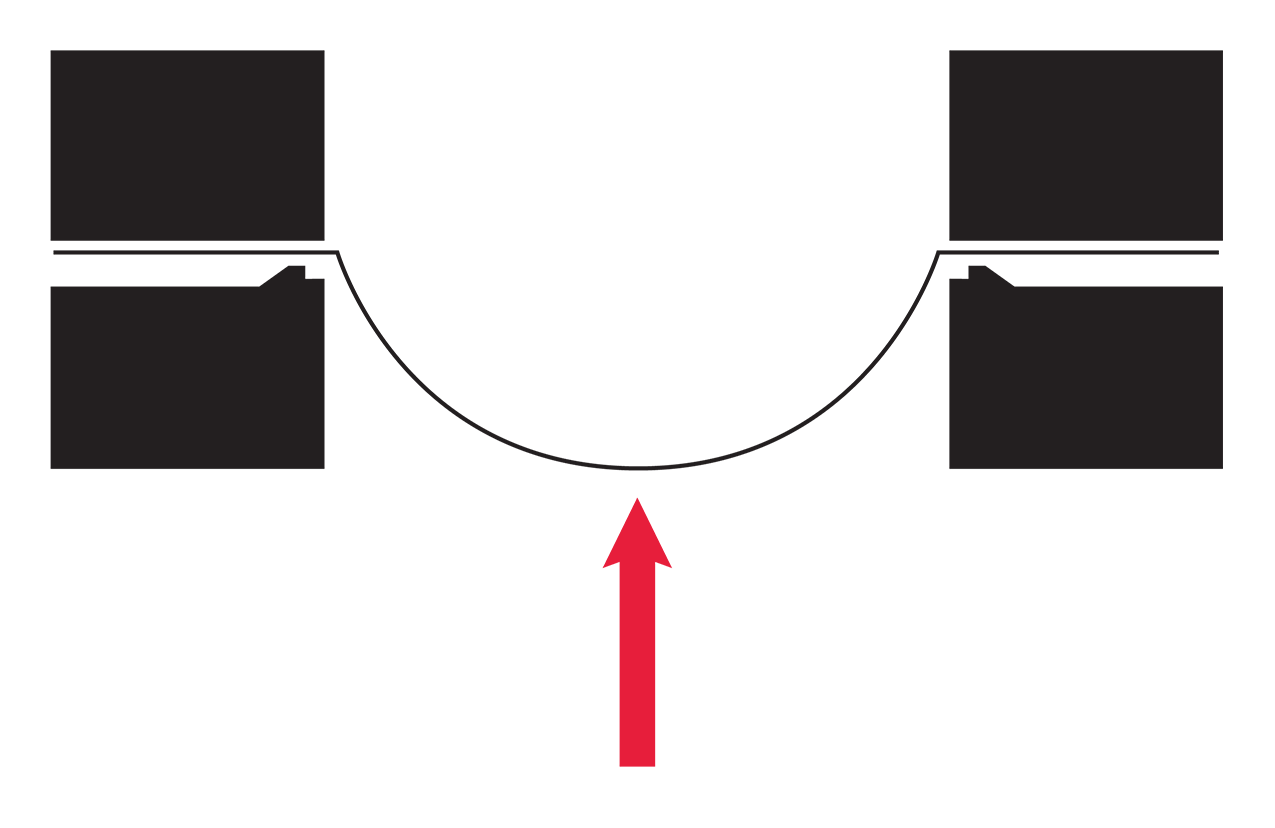

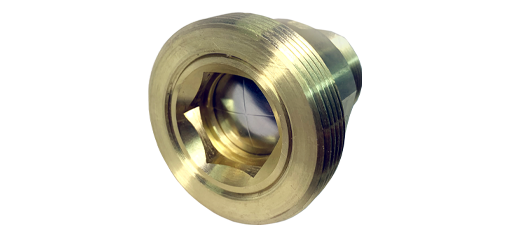

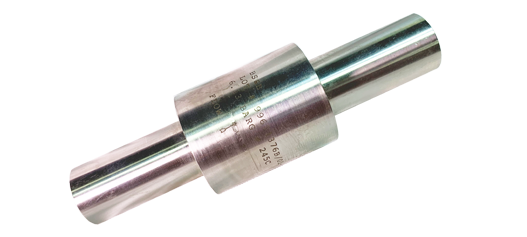

LPS 型破裂板は5 psig (0.35 barg) の低設定圧力に対応するように開発された反転型破裂板です。LPS 型破裂板はSRB-7RS®ホルダーと共に使用することで精度と信頼性が向上します。SAF技術(Structural Apex Forming,構造的向点成形加工)と特徴的で効率的な開口が低設定圧力を実現しています。LPS™ Disk Specifications Minimum/Maximum Pressure with Rating at 72° (22°C)

| Disk Size | Nickel Alloy 200 | Monel® Alloy 400 | Inconel® Alloy 600 | Hastelloy® Alloy C-276 | 316SS | ||||||||||||||||

| in | mm | psig | barg | psig | barg | psig | barg | psig | barg | psig | barg | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | ||

| 1 | 25 | 15 | 70 | 1.03 | 4.83 | 20 | 70 | 1.38 | 4.83 | 20 | 70 | 1.38 | 4.83 | 15 | 70 | 1.03 | 4.83 | 15 | 70 | 1.03 | 4.83 |

| 1.5 | 40 | 6 | 55 | 0.41 | 3.79 | 10 | 55 | 0.69 | 3.79 | 10 | 55 | 0.69 | 3.79 | 7 | 55 | 0.48 | 3.79 | 6 | 55 | 0.41 | 3.79 |

| 2 | 50 | 5 | 40 | 0.34 | 2.76 | 8 | 40 | 0.55 | 2.76 | 8 | 40 | 0.55 | 2.76 | 6 | 40 | 0.41 | 2.76 | 5 | 40 | 0.34 | 2.76 |

| 3 | 80 | 5 | 35 | 0.34 | 2.41 | 7 | 35 | 0.48 | 2.41 | 7 | 35 | 0.48 | 2.41 | 5 | 35 | 0.34 | 2.41 | 5 | 35 | 0.34 | 2.41 |

| 4 | 100 | 5 | 30 | .034 | 2.06 | 7 | 30 | 0.48 | 2.06 | 7 | 30 | 0.48 | 2.06 | 5 | 30 | 0.34 | 2.06 | 5 | 30 | 0.34 | 2.06 |

| 6 | 150 | 5 | 25 | 0.34 | 1.72 | 7 | 25 | 0.48 | 1.72 | 7 | 25 | 0.48 | 1.72 | 5 | 25 | 0.34 | 1.72 | 5 | 25 | 0.34 | 1.72 |

| 8 | 200 | 5 | 25 | 0.34 | 1.72 | 7 | 25 | 0.48 | 1.72 | 7 | 25 | 0.48 | 1.72 | 5 | 25 | 0.34 | 1.72 | 5 | 25 | 0.34 | 1.72 |

| 10 | 250 | 5 | 25 | 0.34 | 1.72 | 7 | 25 | 0.48 | 1.72 | 7 | 25 | 0.48 | 1.72 | 5 | 25 | 0.34 | 1.72 | 5 | 25 | 0.34 | 1.72 |

| 12 | 300 | 5 | 25 | 0.34 | 1.72 | 7 | 25 | 0.48 | 1.72 | 7 | 25 | 0.48 | 1.72 | 5 | 25 | 0.34 | 1.72 | 5 | 25 | 0.34 | 1.72 |

Consult BS&B for applications where the disk may be rated with a coincident temperature below 300°F (149°C) (176°F (80°C) for Hastelloy) but operated at a higher value. Special processing may be required.

Burst Tolerance

Burst tolerance is the +/- range of pressure over which a rupture disk (bursting disc) can be expected to burst.

| Specified Burst Pressure | Burst Tolerance | |

| psig | barg | |

|---|---|---|

| 28 and higer | 1.9 and higher | ± 5% |

| 20 to 28 | 1.4 to 1.9 | ± 7% |

| 10 to 20 | 0.7 to 1.4 | ± 10% |

| <10 | < 0.7 | ± 15% |

| Alternate: < 40 | < 2.76 | ± 2 psig (0.138 barg) |

Standard Assembly Options

Clamped Assembly

Bolted Assembly

Welded Assembly

This customized ready-to-install design simplifies installation and assures leak tightness with its welded construction.

In Line Assembly

TorqueFit Assembly

Components are assembled together using mechanical methods and application of torque provides leak tight seal

Product Literature

概要

LPS 型破裂板は5 psig (0.35 barg) の低設定圧力に対応するように開発された反転型破裂板です。LPS 型破裂板はSRB-7RS®ホルダーと共に使用することで精度と信頼性が向上します。SAF技術(Structural Apex Forming,構造的向点成形加工)と特徴的で効率的な開口が低設定圧力を実現しています。

概要

LPS 型破裂板は5 psig (0.35 barg) の低設定圧力に対応するように開発された反転型破裂板です。LPS 型破裂板はSRB-7RS®ホルダーと共に使用することで精度と信頼性が向上します。SAF技術(Structural Apex Forming,構造的向点成形加工)と特徴的で効率的な開口が低設定圧力を実現しています。